Get Ready to change your Product Vision into Realty...

Fast Delivery And Low MOQ With Money Back Guarantee...

We deliver consistent, high-quality plastic components through advanced tooling, controlled processes, and strict quality inspection standards.

We design and manufacture custom injection-molded parts meeting specific design, material, and functional requirements across industries.

Modern injection molding machines ensure repeatable quality, tight tolerances, and efficient high-volume production cycles.

Diam elitr kasd sed at elitr sed ipsum justo dolor sed clita amet diamFrom prototypes to high-volume manufacturing, we support scalable production while maintaining quality and cost efficiency.

We are a group of trained professionals offering high-quality services in injection mold designs to customers. Our offerings include a wide range of services in injection molding and begin from full design to managing the production. We have in-house 3D equipment that makes the finest prototypes and most of our clients coming from a diverse range of industries including, aerospace, medical, electrical, and computer. Here is why we are the preferred service providers in injection molds designs.

We are dedicated to providing precision, efficiency, and innovative plastic solutions for your manufacturing needs.

We design and produce custom plastic components that meet exact specifications and performance requirements.

Read MoreOur team supports product design and prototyping to ensure a seamless transition from concept to production.

Read MoreWe provide scalable solutions for high-volume production while maintaining strict quality standards.

Read MoreWe work with a wide range of thermoplastics to ensure durability, strength, and application-specific properties.

Read MoreEvery part undergoes rigorous quality checks to ensure consistency, precision, and reliability.

Read MoreWe create precision molds that maximize efficiency and minimize waste.

Read More

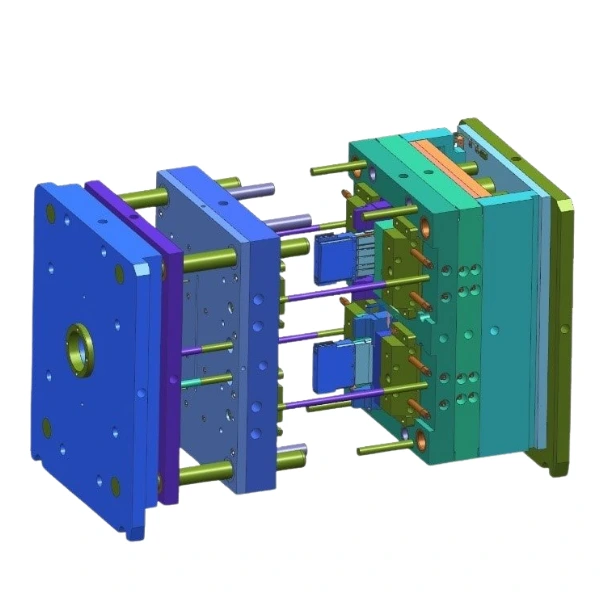

We offer full range of injection molding design from the initial stage to the higher levels, such as tooling, production, and tackling the problems in the post production stage. Backed with a highly qualified team of experts and enthusiastic individuals, we provide mold design for injection molding that is genuinely exceptional. We also have the potential to offer the best tooling solutions to the customers. We have a wide assortment of cutting edge technology and tools to deliver injection molding solutions to the customers. We maintain an interactive relationship with the customers.

We are experts in technology in customized design for injection molding and one of the most renowned service providers. Being experts in the field of injection molding, our wealth of knowledge and skills of catering to a diverse base of customers is an advantage. For assistance in injection molding and tool-making, you can feel free to contact us anytime.

We provide a diverse range of solutions that cater to the bespoke requirements of customers in injection molding mold design tooling, and providing support in the post molding stage. Here is what you need to know.

We have a dedicated team of experts for molding and tooling and cater to a wide range of industry sectors, such as aviation, electronics, medical and aviation.

As a leading plastic injection molding company, our team of injection mold designers plays a critical role in ensuring the production of high-quality parts of molds. In this blog post, we will discuss the importance of mold designers in the plastic injection molding process and their impact on the overall quality of the final product.

Role of Injection Mold Designers

Importance of mold designers

Impact of mold designers on the final product

The final product is only as good as the mold used to create it. Poorly designed molds can result in parts that do not meet the required specifications. This can lead to costly production delays and even product recalls. Mold designers are critical in ensuring that the final product meets the desired quality standards.

The plastic injection mold design affects the part geometry and surface finish. A well-designed mold will produce parts with consistent wall thickness, and smooth surfaces free from defects. Mold designers must also consider the post-processing requirements of the part, such as painting, plating, or assembly, to ensure that the mold produces parts that meet these requirements.

We value your time and ideas. Expect quick replies, transparent processes, and expert advice for your project requirements.

Our company gains strength from customers when dealing with injection mold runner design and have always enjoyed the harmony in maintaining the relationship with the customers. The outstanding commitment towards quality during runner design for injection molding and the affordability of rates makes us one of the most trusted manufacturers in this field.

The parts we produce undergo validation to ensure that they can sustain the load conditions appropriately. With the implementation of scientific methods, we can rectify the inconsistencies in the part; make sure about the existence of repeatability and boost the efficiency to the highest level.

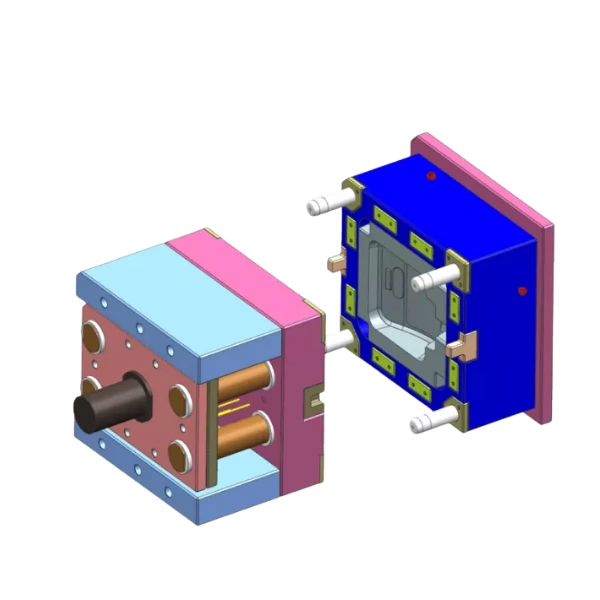

At Plastic Injection Molding, we pride ourselves on producing top-quality injection moulding die design that meet our client's needs. Our expertise in injection molding dies and manufacturing has enabled us to deliver innovative solutions that meet the most demanding specifications.

The design of injection molding dies is a critical process that requires a deep understanding of the product requirements, the material properties, and the manufacturing process. Our team of experts uses the latest tools and techniques to design dies that meet the most complex requirements.

Considering factors when designing injection moulding dies

What sets us apart

Welcome to our blog on commercial molding! At Plastic Injection Molding, we are dedicated to providing high-quality, custom industrial moulds for businesses in a variety of industries. Our team of experts has years of experience in the field and can help you improve your manufacturing process with our custom molding solutions.

What is custom industrial molding?

Commercial molding is a manufacturing process that involves shaping materials into specific forms using custom molds. This process is commonly used in industries such as automotive, aerospace, medical, and consumer goods.

The molds used in commercial molding are designed to be highly precise and durable, allowing for the creation of consistent, high-quality products.

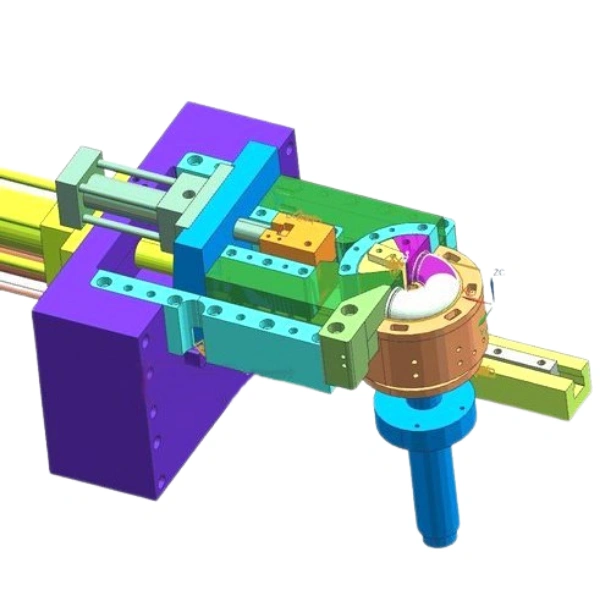

Have you ever wondered how cool things like toys and gadgets are made? Well, meet the superhero of manufacturing: injection moulding tooling! This incredible tool works like magic, turning melted material into perfect shapes. Think of it as a special mold that brings your favorite things to life. Engineers design it super carefully, making sure everything is just right – like how the material flows and how the final product comes out. It's not just about making stuff; it's about using the power of injection moulding tooling to create amazing things that make our lives more fun and convenient!

Imagine making toys, phone cases, or car parts. Injection molding tool design is like creating a special mold for these things. It's a cool process where designers make sure the mold is just right to make perfect products. We think about how the material flows, how it cools down, and how to take the product out smoothly. It's like an art, mixing creativity and smart planning. From the first idea to the final touch-ups, every step in making the mold is super important. This whole process is like a magic trick that helps us get awesome stuff in our hands!

There are several reasons to choose us to fulfill your commercial requirements:

Our molding services

If you want to enjoy the best services from experts in injection molding, call us today toget the finest level of services and assistance.

Get Ready to change your Product Vision into Realty...