Get Ready to change your Product Vision into Realty...

Fast Delivery And Low MOQ With Money Back Guarantee...

We deliver consistent, high-quality plastic components through advanced tooling, controlled processes, and strict quality inspection standards.

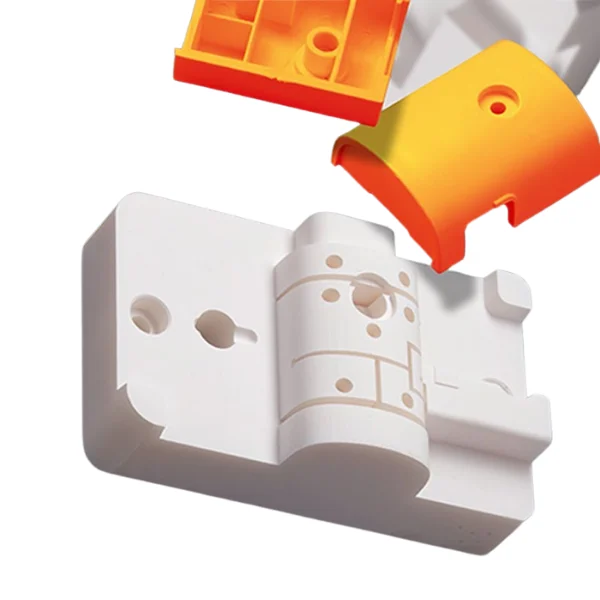

We design and manufacture custom injection-molded parts meeting specific design, material, and functional requirements across industries.

Modern injection molding machines ensure repeatable quality, tight tolerances, and efficient high-volume production cycles.

Diam elitr kasd sed at elitr sed ipsum justo dolor sed clita amet diamFrom prototypes to high-volume manufacturing, we support scalable production while maintaining quality and cost efficiency.

If you are thinking of improving your business strategy and enhance the speed of your innovation, you can avail our 3d Mould Design service and make the most of the qualifications and experience of the experts. For high-quality and graded products, you can rely on our 3D prototyping service and bring your design concepts to life. Here are the three basic aspects of our company.

So, it’s time to optimize your part design and analyze the opportunity of additive manufacturing projects with us. Give us your concept and get advice from our design experts.

We are dedicated to providing precision, efficiency, and innovative plastic solutions for your manufacturing needs.

We design and produce custom plastic components that meet exact specifications and performance requirements.

Read MoreOur team supports product design and prototyping to ensure a seamless transition from concept to production.

Read MoreWe provide scalable solutions for high-volume production while maintaining strict quality standards.

Read MoreWe work with a wide range of thermoplastics to ensure durability, strength, and application-specific properties.

Read MoreEvery part undergoes rigorous quality checks to ensure consistency, precision, and reliability.

Read MoreWe create precision molds that maximize efficiency and minimize waste.

Read More

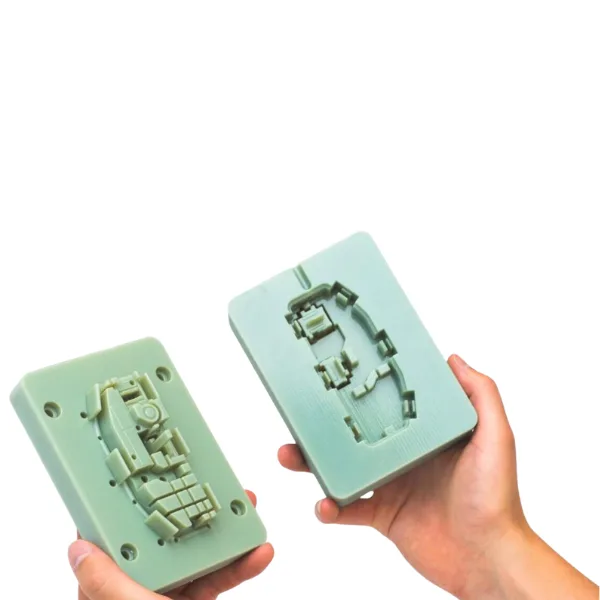

We provide 3D mold design on demand along with processes, technologies, tools, and skills to translate your design ideas into fully manufactured parts. From rapid prototyping, functional prototyping, and low-volume manufacturing, we have the proven skills to fabricate the parts. Our customer base has taken to the higher level to aid the requirements of customers through high speed and time-to-market. We are happy to access a broad range of materials and processes to meet the preferences of rapid 3D prototyping across the world.

Imagine bringing your idea into reality. 3D mould design acts as a blueprint of your product for manufacturing. Our team utilizes 3D modeling softwares to create high-quality mold designs, ensuring efficient production and exceptional results.

We value your time and ideas. Expect quick replies, transparent processes, and expert advice for your project requirements.

Our 3D rapid prototyping service is an on-demand facility wherein you can get quick design iterations, scale models, and speedy product development at your fingertips. The services of our company can help the engineering and design team to turn the concepts and ideas into reality pretty fast. Whether it is concept testing of obtaining real-time feedback of the product design, we can meet your requirements quickly and effectively. Here is what you need to know about our 3D prototyping service .

Our 3D printers can generate plastic models and accurate functional prototypes or end use parts to optimize the 3D prototype design make your work flow smooth, and help in launching highly innovative products in the market. Moreover, the printers we own provide speedy service, reduce the cost, and enhance the efficiency. Know the following.

Contact us for 3D rapid prototyping service today.

Get Ready to change your Product Vision into Realty...