Fast Delivery And Low MOQ With Money Back Guarantee...

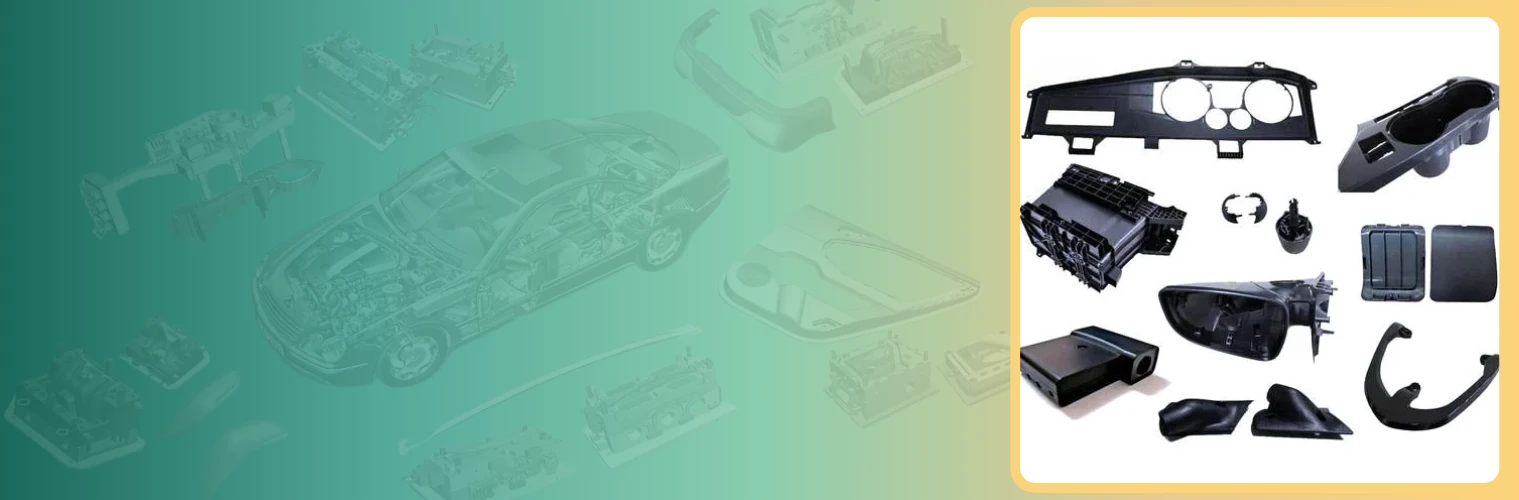

Automotive injection molded parts are a vital part used in automotive manufacturing. These parts, whether lightweight or made from high-strength engineering plastics, help to improve performance, reduce costs, and ensure long-lasting durability.

Whether used in traditional IC engine vehicles or modern EV platforms, these molded parts are essential for efficiency, safety, comfort, and innovative design. The following section explains the main categories shaping the future of automotive plastics

The use of automotive injection molded parts is massive because of their robustness, accuracy, and flexibility to design. We depend on sophisticated molding technology to be able to manufacture both functional and aesthetic uniform quality plastic parts.

Highlights:

Plastic manufacturing, whether it is an interior, exterior, or structural part, offers unsurpassed versatility, regardless of the dashboards, door trim, or any other components.

The comfort and style are reflected in the interior of the vehicle. Injection molding for car interior parts are used to manufacture components of different cabin parts that have better fit, smooth finish, and durability of the appearance.

Common Interior Parts:

Apart from making it more appealing to the eye, injection molding also makes it safe using flame-resistant and impact-resistant materials.

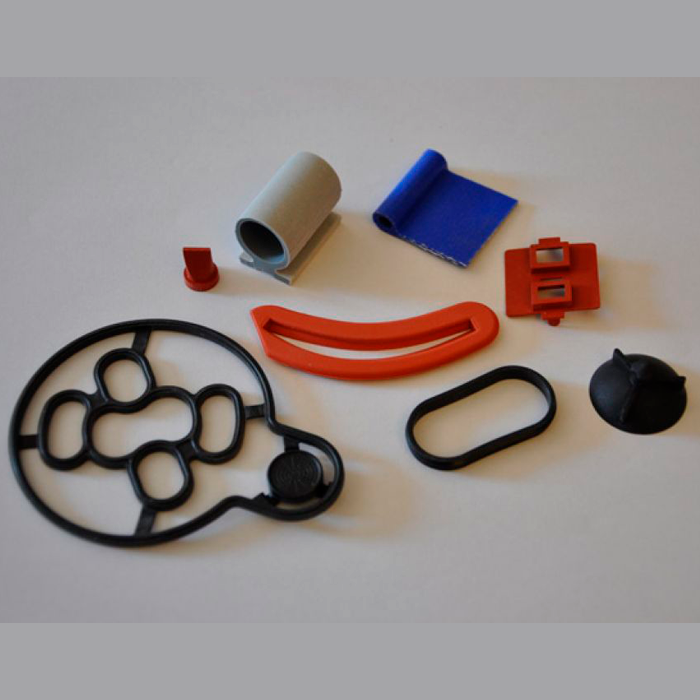

Lightweight Plastic Automobile Parts has been one factor that has taken centre stage in the automotive industry in a bid to enhance energy efficiency, speed, and the performance. Plastic components save a lot of weight to the vehicle without affecting its strength.

Lightweight Plastics have the following advantages:

Bumper reinforcements, structural brackets, and lightweight plastic parts are commonly used in modern automotive engineering.

One of the most popular materials used in automotive injection molding due to its toughness and versatility is ABS (Acrylonitrile Butadiene Styrene).

Key benefits of this molding includes:

Applications of ABS include dashboards, seat backs, grilles, mirror covers, pillar covers and several pillar supports.

We believe in providing reliable, innovative, and cost-effective plastic injection molding solutions. Your trust allows us to deliver products that are precise, durable, and reliable.

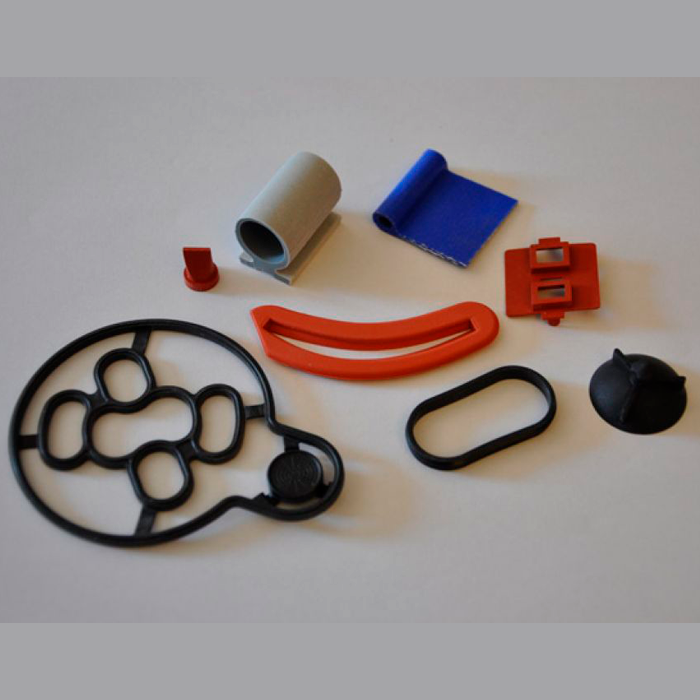

The vehicles that are powered by electricity need highly manufactured plastic parts to aid in efficiency, heat management, and light weighting. Investing in EV Plastic Component Injection Molding is the best option when it comes to the manufacturing of EV.

Advantages of Electric Vehicle Components

EV plastic parts consist of motor housings, battery module support, wiring connector, charging parts, and aerodynamic exterior parts.

The most popular examples of large scale components that are manufactured on the basis of high level technologies are Molded Dashboards and Bumpers. These components must be strong and of high quality.

Key Features:

Bumpers are molded to enhance the performance of the car during a crash and dashboards are designed to assure ergonomic and comfort to the drivers and passengers.