Fast Delivery And Low MOQ With Money Back Guarantee...

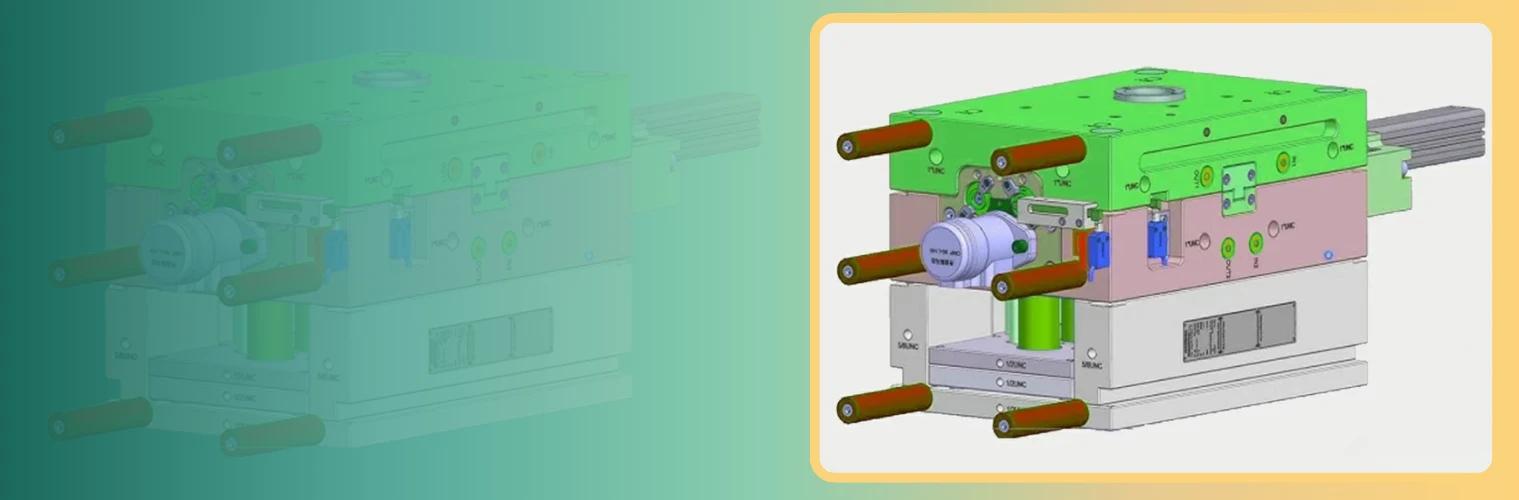

The core of reliable and high-quality precision mold making services lies in a combination of engineering expertise, material knowledge, advanced manufacturing processes like CNC machining, EDM technology, and strict quality checks.

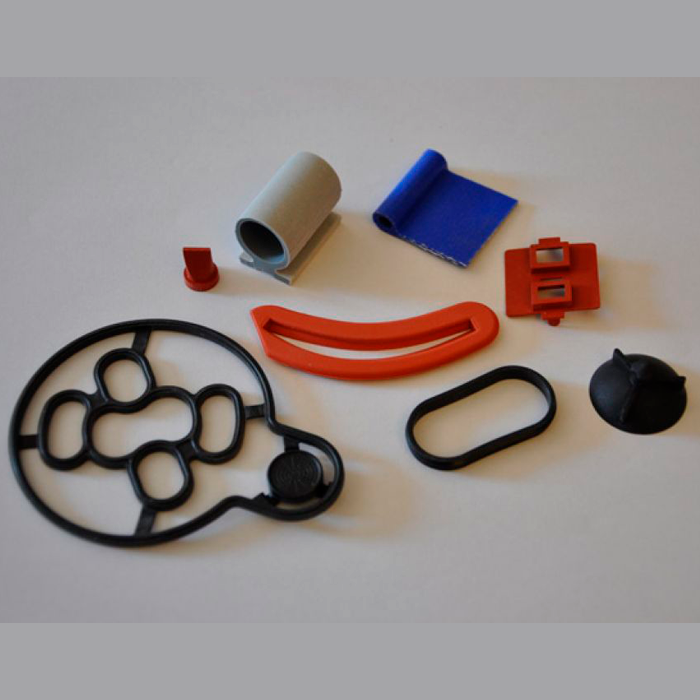

Regardless of whether you manufacture consumer products, auto parts, medical devices or industrial parts, the quality of product will be determined by the quality of your mold.

The precision mold making services ensure smoother manufacturing, longer mold life, and lower operating costs. These services provide accurate and dimensionally stable molds to meet the complex needs of the industry.

High-precision mold builders specialize in designing and manufacturing complex molds with exceptional accuracy. They ensure consistent quality, tight tolerances, and reliable performance for demanding application

Core Capabilities:

Multi-cavity mold designs enable the production of multiple identical parts in a single molding cycle. These designs ensure consistent quality and uniform dimensions across all molded components.

Key Advantages:

Mold maintenance and repair services ensure consistent mold performance and extended tool life. Regular inspection and timely repairs help prevent downtime, defects, and unexpected production delays.

Service Highlights:

The prototype mold construction allows manufacturers to test and validate design functionality before full-scale production. It helps identify potential issues early, reducing risks, rework, and overall development costs.

Key Advantages:

We believe in providing reliable, innovative, and cost-effective plastic injection molding solutions. Your trust allows us to deliver products that are precise, durable, and reliable.