Metal Injection Molding

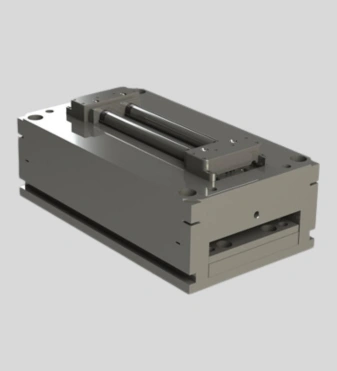

Custom Designs

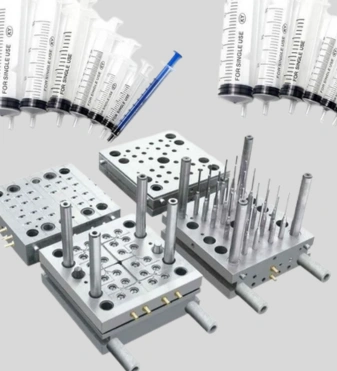

Precision Fit

Smooth Edges

Longer service life

Accurate Dimensions

Book a 20 Min. Strategy Call

When you intend to produce parts in large volumes, applying the injection molding process is the best idea. The manufacturing process, in general, involves the injection of molten materials into a mold. The metal injection molding process is a specialized version of the molding process where the manufacturer combines finely powdered metal with some thermoplastic binder material to create the feedstock.

The change of raw material for the molding can help to manufacture the appropriate qualities of the parts.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Advanced Molding Process In Industry

The use of liquid silicone in silicone injection molding has become a revolutionary advancement in manufacturing parts, especially in the automotive and healthcare industries. The high consistency of liquid silicone supports the production of parts for industries like aerospace, electronics, infant care, automotive, and many more.

When conventional machining fails to perform, the ceramic injection molding technology comes to the rescue. It is ideal when you have to produce complex shapes of the parts or some intricate designs in the small parts. The use of sub-micron ceramic powder provides the best surface finish.

Countries

Industries Served

Projects

Clients

As the demands of the customers increase every day, you need to be creative even in the designs of the conventional parts to draw the attention of customers. The liquid injection molding technique allows you to achieve perfection in the intricate designs, too, by the use of injecting liquid raw material inside the molds. Impacting the shapes and designs has never been easier.

Are you planning to fulfill huge orders that need extensive manufacturing? Then the hot runner injection molding process can probably help you the most.

It is also possible to supply in bulk with the thermoset injection molding process. All of these procedures are capable of delivering premium quality products. To create lightweight plastic parts, you can even apply the thin wall injection molding technique. It is the modernized way to make them highly durable but lightweight instruments, devices, and tools for many industries. But the design is complex and needs minute detailing.