Automotive

High Durability

Safety Assurance

Lightweight Design

Custom Components

Quality Manufacturing

- Home

- Custom Automotive Plastic Parts

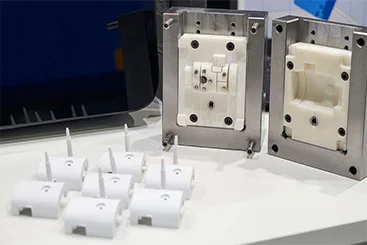

Plastic Injection Molding For The Automotive Industry

At Plastic Injection Molds, we’ve spent years working closely with automotive teams, and one thing remains constant: we handle every project with care. That same dedication goes into every automotive plastic injection molding project you trust us with. We listen and try to understand exactly what you’re trying to achieve.

A part isn’t “just a part” to us; it’s something that impacts the feel, safety, and value of the vehicle you’re manufacturing. That’s why we pay close attention to the details when shaping custom automotive plastic parts, whether it’s something exterior, interior, or deep inside the engine compartment.

If you are seeking injection molded car components that can resist extreme heat, vibration, and long-term use, we take your expectations seriously. The same goes for auto interior plastic parts molding—we know comfort, appearance, and smooth finishing matter.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Custom Rubber Extrusion Solutions with Proven Expertise

1395 projects & 690 happy clients.

At Custom Rubber Extrusion, our focus is on designing and manufacturing Extrusion products specifically designed to meet the individual needs of each of our customers. We have a decade of experience in the industry, during which we've successfully delivered over 1395 projects for a wide range of industries, and are proud to have served more than 690 happy clients.

We customised every Extrusion to meet your exact requirements, guaranteeing durability, dependability, a perfect fit, and top-notch performance. Whether it's for the automotive, oil and gas, construction, chemical, or general industrial sectors, our products are made with precision to handle the toughest conditions.

5+

Countries

11+

Industries Served

1395+

Projects Completed

690+

Clients

PLASTIC INJECTION MOLDS

Industry Served

Why Choose Us

Plastic Injection Molds Solutions With Proven Expertise

Over time, we’ve worked with 12 industries, wrapped up 1,850+ projects, and supported 870+ clients across different regions. Every one of those experiences taught us something new about automotive plastic injection molding and how to serve clients better. As long-standing automobile plastic mold manufacturers, we’ve learned how to guide customers through complicated technical challenges without making the process stressful.

Whether you need custom automotive plastic parts for small batches or long runs of injection molded car components, we help you move through each stage with clarity and confidence. Many clients choose us for auto interior plastic parts molding because they know we stay consistent and dependable, no matter how demanding the project may be.

Importance of Plastic Injection Molding in the Automotive Industry

Today’s automotive market highly depends on plastic injection molding. It helps manufacturers make vehicles lighter, improve fuel efficiency, and still keep the strength and durability where it matters most. Auto interior plastic parts molding helps create the trims, panels, vents, and comfort-focused features that drivers interact with every day.

On the performance side, injection molded car components help support airflow, wiring, temperature control, and safety systems. By choosing capable automobile plastic mold manufacturers, you gain access to stable production, precision, and long-lasting custom automotive plastic parts. For most businesses, plastic injection molding is frequently preferred as it helps to maintain the cost, efficiency, and quality.

Range of Our Plastic Injection Molded Products for the Automotive Industry

- Our team creates a wide variety of injection molded car components to support different areas of your vehicle’s design and performance.

- Dashboard trims and panels – Made with auto interior plastic molding for clean, attractive surfaces that improve the cabin’s look.

- Door handles and inner panels are light but robust, which feel nice on the touch and will survive the years of use.

- Air vents and HVAC components hold true to their functionality and reliability in airflows, serving quality comfort for everyone inside.

- Engine covers and protective casings - Durable, heat-resistant parts designed to withstand the extremes of heat and constant pressure under the hood.

- Connectors, clips, and fittings-small but mighty components that keep the whole vehicle together in terms of assembly and performance in stability and safety overall.

Advanced Solutions for Automotive Plastic Injection Molding

Our approach to automotive plastic injection molding goes beyond the basics. We use digital simulations, detailed modeling, and material planning to understand how a part will behave once it is used in the vehicle. When creating custom automotive plastic parts, we consider not only the dimensions but also how the user will feel when interacting with the piece. Auto interior plastic parts molding requires a balance of strength, smooth touch, and appealing appearance, and we pay close attention to all three.

As reliable automobile plastic mold manufacturers, we adjust processes to bring more consistency, fewer defects, and smoother scaling for injection molded car components. No matter the size or complexity of the part, we stay involved, communicate openly, and help you get results you can trust.

If you’re searching for a team that takes automotive plastic injection molding seriously and cares about your goals, we’ll be glad to support you. Let us help turn your custom automotive plastic parts and injection-molded car components into reality. With care, precision, and a team that truly cares about your project, we’ll make it happen. Contact us today to get started!

Call: +1 (647) 294-5240

Ready to See your Idea For Plastic Injection Molds

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.