- Home

- Mold Components Cavity Core Hot Cold Runner

Cavity, Core, Hot Runner, Cold Runner — Complete Mold Components Guide

Manufacturers like us rely on efficient and accurate tooling systems to maintain high production standards. This mold components guide shows how the mold cavity core system, along with hot runners and cold runners, works together to improve melt flow, ensure consistent part quality, and boost overall molding efficiency for better, more reliable manufacturing performance. It helps teams make smarter tooling decisions. This foundation supports long-term production success.

1. Understanding the Mold Cavity Core System

An injection mold has two halves. One half, the core, creates the inner details like holes, while the other, the cavity, shapes the outside. When these two fit together perfectly, the result is a part that’s precise, clean, and just as it should be—a small thing, but it makes all the difference. Our experience shows that careful alignment, venting, and surface finishing inside this system directly influence part strength, weight, and dimensional stability.

1.1 Role of the Cavity: The cavity forms the outside profile of the part. For thin-walled parts, clear optical components, or transparent packaging, the cavity surface is polished for smooth, clean results. A properly designed mold prevents twisting or uneven shrinkage and ensures every part generated is accurate and consistent.

1.2 Role of the Core: The core manages internal shapes such as holes, ribs, and recesses. Manufacturers like us reinforce core pins and inserts to withstand pressure and repeated cycling. With smart design, the mold cavity core system supports longer mold life and consistent part quality in high-volume programs.

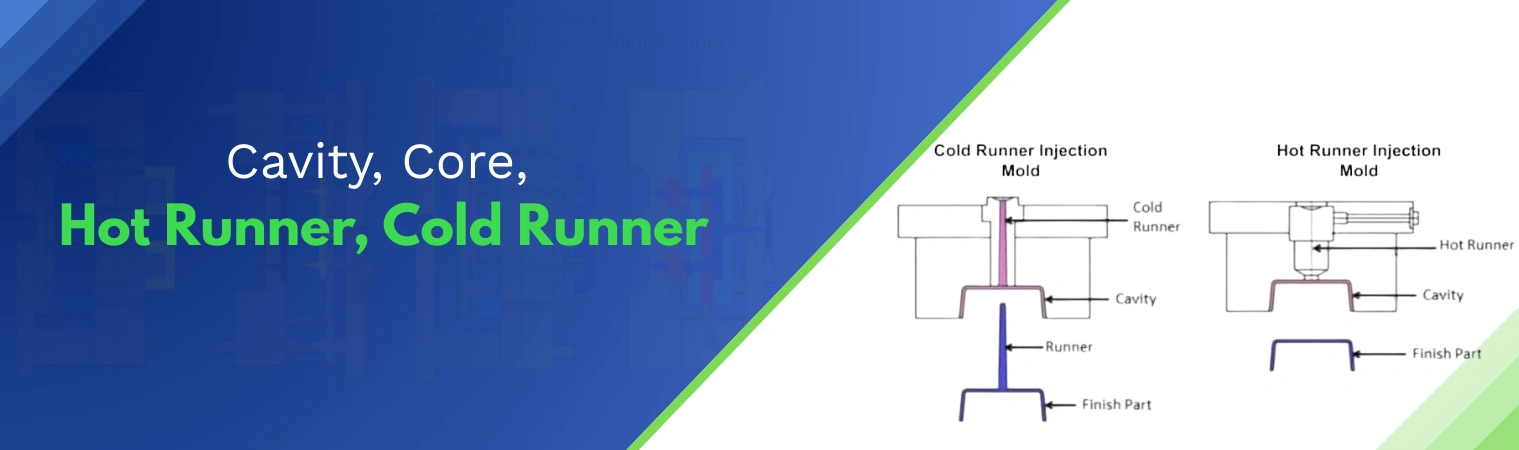

2. Hot Runner vs Cold Runner — Key Differences

Choosing between these two systems determines melt flow efficiency, molding speed, and scrap levels. Our mold components guide explains how each system behaves under real working conditions.

2.1 What Are Hot Runners?

Hot runners use heated manifolds and nozzles to keep plastic molten until it fills the cavity. As a result, they eliminate runners and reduce secondary trimming. When comparing hot runners with cold runners, choose hot runners for faster cycles, automated production, and reduced raw material waste.

2.2 What Are Cold Runners?

Cold runners channel molten resin through unheated runners, which solidify and must be trimmed after molding. In the hot runner vs cold runner comparison, cold runners remain a cost-effective choice for simpler parts, lower volumes, and frequent material changes because they prevent color contamination.

2.3 Selecting the Right Runner System

We help manufacturers analyze resin type, cycle time, tooling budget, and part complexity. In many programs, hot runner vs cold runner selection impacts tooling cost far more than part cost. That’s why we provide guidance on thermal balance, manifold design, sprue sizing, and shear-sensitive materials.

3. How the Core and Cavity Work Together

Knowing how the core and cavity work together during molding helps make sure every part comes out correctly.

3.1 Mold Closing: When the mold closes, the cavity and core fit together to shape the part. Centering locks, leader pins, and custom alignment keys help ensure consistent seating every cycle.

3.2 Melt Injection: The molten polymer flows from the runner system into the cavity. Here, the quality of the mold cavity core system directly affects packing pressure, crystallization, and cooling uniformity.

3.3 Ejection: After cooling, pins or plates push the part out of the mold. A good mold components guide helps it come out smoothly without marks or damage.

4. Cooling System Essentials

Efficient cooling can take up over 70% of the molding cycle. Cooling channels should be designed around the cavity and core to keep temperatures steady and reduce the overall cycle time.

4.1 Conformal Cooling: For complex designs, conformal cooling channels allow better heat extraction and shorter cycles. This feature enhances part quality, especially when runner selection (hot or cold) changes thermal profiles.

4.2 Steel and Insert Choices: Tool steel selection—P20, H13, S7, or stainless inserts—directly influences longevity and thermal control. These steel and insert choices help manufacturers match steel grades with resin types like PVC, ABS, PP, or nylon.

5. Maintenance and Troubleshooting

Upkeeping the mold cavity core system ensures stable performance throughout its life. Our team performs preventive maintenance, including polishing, vent cleaning, and runner inspections.

5.1 Runner System Checks: During maintenance, we review nozzle tips, gates, manifolds, and sprues. Whether evaluating hot runner vs cold runner systems, we monitor heat zones, insulation plates, and flow channels for optimal performance.

5.2 Wear and Tear in Cavities and Cores: Over time, high-glass-filled or abrasive materials can erode cavity and core surfaces. By following our mold components guide, manufacturers can prevent flash, short shots, and dimensional inaccuracies.

Why Choose Plastic Injection Molds?

At Plastic Injection Molds, we are driven by core values that guide our business and define our commitment to our clients.

Expertise and Experience - With years of experience in the Plastic Injection Molds industries, we have the expertise to deliver custom-designed solutions that meet the most demanding requirements.

High-Quality Products - Our Plastic Injection Molds are made from high-quality materials, ensuring durability, clarity, and long-lasting performance.

Custom Solutions - We specialize in providing tailored Plastic Injection Molds solutions that meet the unique needs of our clients.

Exceptional Customer Service - We provide end-to-end support, from initial consultation to post-delivery assistance, ensuring our clients are delighted with the results.

Do you want to work with us to turn ideas into a reality for plastic molding projects? Call us at +1(647)294-5240 or send us an email at info@plastic-injectionmolds.com. We will work with you fast and easy for you to manufacture with confidence.

Ready to See your Idea For Plastic Injection Molds

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.