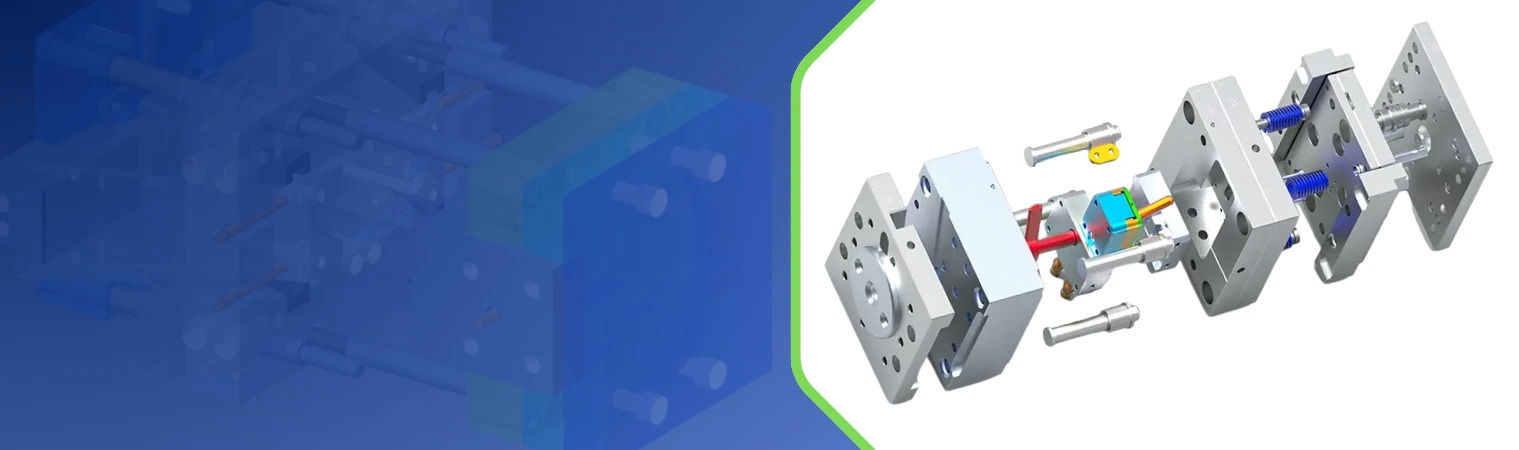

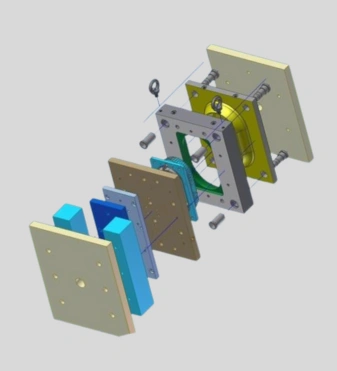

Injection Mold

Custom Designs

Precision Fit

Smooth Edges

Longer service life

Accurate Dimensions

Book a 20 Min. Strategy Call

The popularity of injection molded plastic parts has been growing over the last few years and the primary reason is that the process allows companies to achieve highest scalability. When working with a reputed injection mold designer, you will find it easy to create complex and simple parts that are uniform. Moreover, the experts will allow you to make hundreds of identical parts with ease.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

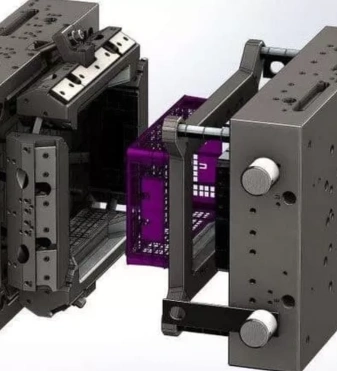

Mold Designing In Industry

One of the major challenges that experts face during injection mold design is to provide transparency to the objects and making them tolerant towards the temperature variations. We coordinate with the clients and discuss the specifications of critical tolerance and consider different modifications of mold when needed. Therefore, the manufacturers of injection molded parts need to instill the features need to give the product extra clearance. Here are the benefits to maximize the use of plastic parts when working with reliable injection mold designers with ease.

We are one of the most reliable and reputed designers producing plastic mold designs to cater to the requirements of customers, out experts handle small production runs and large batches of molded parts with equal ease. If you want to order bulk product from us, you are sure to get in touch with us soon. Here is why you need to rely on our mold design capabilities.

We are a reliable injection mold designer, so callus today to book the orders.

Countries

Industries Served

Projects

Clients

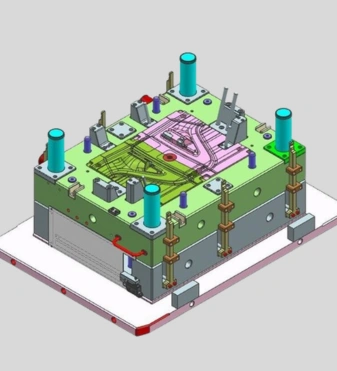

No matter how well you believe you understand how to create components for injection moulding design, you should always establish a tight working relationship with your desired molder as soon as feasible. Every mold design companies has unique preferences for tooling and molding methods, which can have a big impact on component design.

Since choosing a molder is frequently delayed until the design is finished and released for official quoting by the buying department, it can be challenging for designers and engineers to establish this connection early in the design process. Additionally, a lot of molders won't provide any suggestions unless they are certain they will be given the assignment but this is not the case with plastic injection molds

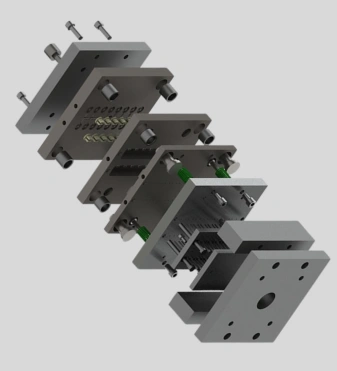

Materials are frequently defined early in the injection mold designs process, and both parties should agree on them. Molders occasionally have the opportunity to buy certain resins in bulk at significant savings. Customers may benefit from these savings.

Due to their viscosity, high glass content, or crystallinity tolerances, certain high-performance resins might not be the best choice for a moulder, as discovered by a designer.

Leaving adequate room in the design for tolerance variation is one of the biggest problems every mold design companies has when creating an injection-molded product. Material composition, process management, and tool design are just a few of the factors that affect tolerance variation. From one molder to the next, acceptable tolerance limits in a design will differ significantly.

Injection molded items, and avoiding sink marks are a constant problem for skilled designers.steel-safe zones Snap fittings, alignment features, and interlocking pieces are a few examples of elements that require close tolerances when constructing injection molded parts. These characteristics can be exactly aligned and matched in CAD with ease, but reproducing them repeatedly during manufacturing is more difficult. Details that cannot be reliably replicated by a molder are frequently designed to be "steel safe."

The ideal situation would be for a designer, molder, and mold design companies to specify the gate placement. Almost every characteristic of an injection-molded object depends on the placement of the gate. It influences, among other things, physical qualities, warpage, tolerances, surface polish, and wall thickness.