Epdm Extrusion

Weatherproof

UV Resistant

Long Durability

Premium Quality

High Performance

SLS 3D Printing

Custom Designs

Precision Fit

Smooth Edges

Longer service life

Accurate Dimensions

Custom 3D Printing

Heat Resistant

Long Durability

Protective Sealing

High Compression

Customizable sizes

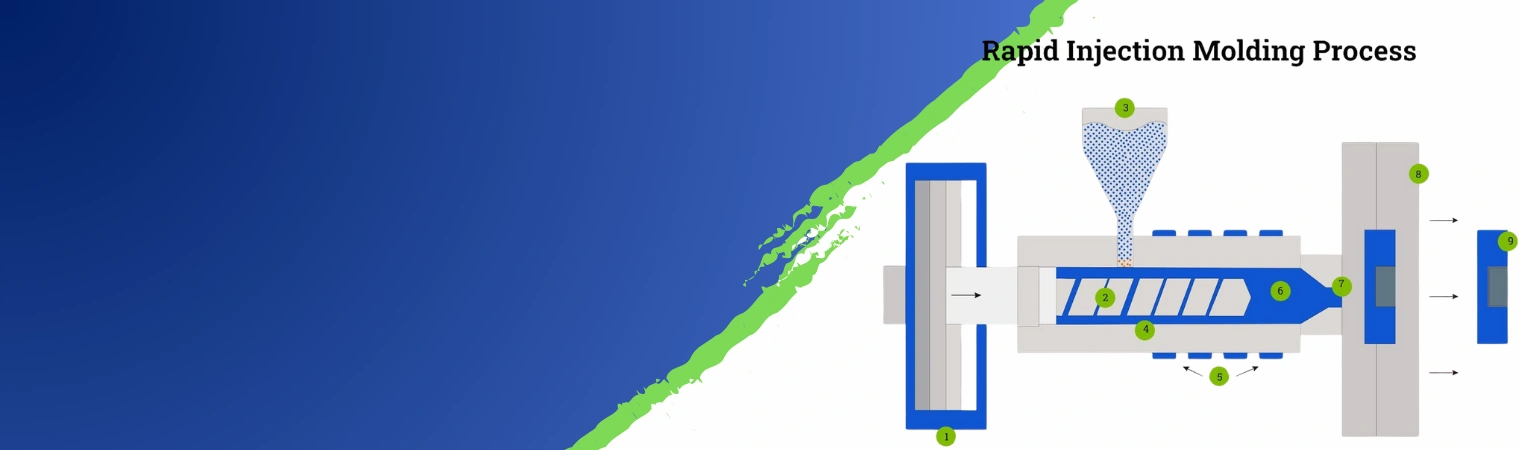

Rapid Injection Moulding

High Elasticity

Reliable Sealing

Custom Sizes

Weather Resistant

Superior Performance

Mold Manufacturer

Perfect Fit

Anti-Vibration

UV Resistant

High Precision

Easy Installation

Custom Mold

High Durability

Smooth Finish

Superior Quality

Custom Shapes

Versatile Use

Plastic Molded Products

Smooth Flow

High resilience

Custom Lengths

Leak Prevention

Chemical resistant

- Home

- Custom Molded Aerospace Plastics

Plastic Injection Molding for the Aerospace & Defense Sector

At Plastic Injection Molds, we manufacture precision plastic parts ready for the aerospace and defense sectors. We know that any part has to work right and also withstand all possible punishment.

With many years of experience, we assist OEMs and Tier-1 suppliers in developing parts that can withstand the stringent requirements of the standards in the real world. With the industry moving towards weight optimization, fuel efficiency, and advanced material engineering, the demand for lightweight injection-molded parts is on the rise.

Our team partners with you closely to develop custom molded aerospace plastics within aerospace-grade specifications, given thermal stability and long-term structural performance expectations. We also cater to non-critical aircraft plastic parts, such as interior cabin parts, housings, and protective enclosures. With our synthetic molds, we create parts that are consistent, reliable, and designed to meet global manufacturing standards.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Custom Rubber Extrusion Solutions with Proven Expertise

1395 projects & 690 happy clients.

At Custom Rubber Extrusion, our focus is on designing and manufacturing Extrusion products specifically designed to meet the individual needs of each of our customers. We have a decade of experience in the industry, during which we've successfully delivered over 1395 projects for a wide range of industries, and are proud to have served more than 690 happy clients.

We customised every Extrusion to meet your exact requirements, guaranteeing durability, dependability, a perfect fit, and top-notch performance. Whether it's for the automotive, oil and gas, construction, chemical, or general industrial sectors, our products are made with precision to handle the toughest conditions.

5+

Countries

11+

Industries Served

1395+

Projects Completed

690+

Clients

PLASTIC INJECTION MOLDS

Industry Served

Why Choose Us

Plastic Injection Molds Solutions with Proven Expertise

At Plastic Injection Molds, we promise to provide years of experience in manufacturing services. A few facts about us include: 870 customers served, 1,850 projects delivered, and artificial industry service of types ranging from automotive through electronics, medical devices, aerospace, LED lighting, and defense. Partnering with companies worldwide, we provide custom aerospace plastic parts, precision molds, and parts that meet strict global standards. With our expertise in custom plastics, strong tooling, and advanced manufacturing, we create high-quality, lightweight injection molded parts and non-critical aircraft components you can trust.

Importance of Plastic Injection Molding in Aerospace & Defence

- Lighter Parts - Plastic injection molding makes airplane parts lighter than metal ones, and this allows better plane performance and payload.

- Precise Fit - Our aerospace molds will make shapes and dimensions that fit perfectly for complex assemblies.

- Cost Savings - Injection molding, especially for non-critical components, lowers the cost per part in large programs.

- Strong Materials - Special plastics will resist UV, fire, impact, and chemicals, which makes them best suited for aerospace parts.

- Consistent & Scalable – Molding generates parts that are the same every time, which is essential for aerospace and defense standards.

Benefits of Our Plastic Injection Molded Products for Aerospace & Defence

- Exceptional Lightweight Performance: We create lightweight plastic parts that help reduce aircraft weight while keeping structures strong. These parts resist corrosion and last longer than metal under repeated use.

- Strong and Heat-Resistant – Our aerospace plastic parts are made from advanced plastics that handle extreme temperatures, vibrations, and mechanical stress common in flight.

- Perfect for Non-Critical Parts – We make aircraft plastic components that are strong, durable, and fit perfectly, without the extra weight of metal.

- Custom Molding Solutions – Our aerospace plastics are designed with care so they can handle complex shapes and meet the tough demands of modern aerospace projects.

- Durable, High-Repeatability Tooling: Our plastic molds made for the aerospace industry are designed for precision, faster production, and long-lasting use, so that you get consistent, high-quality parts even in large quantities.

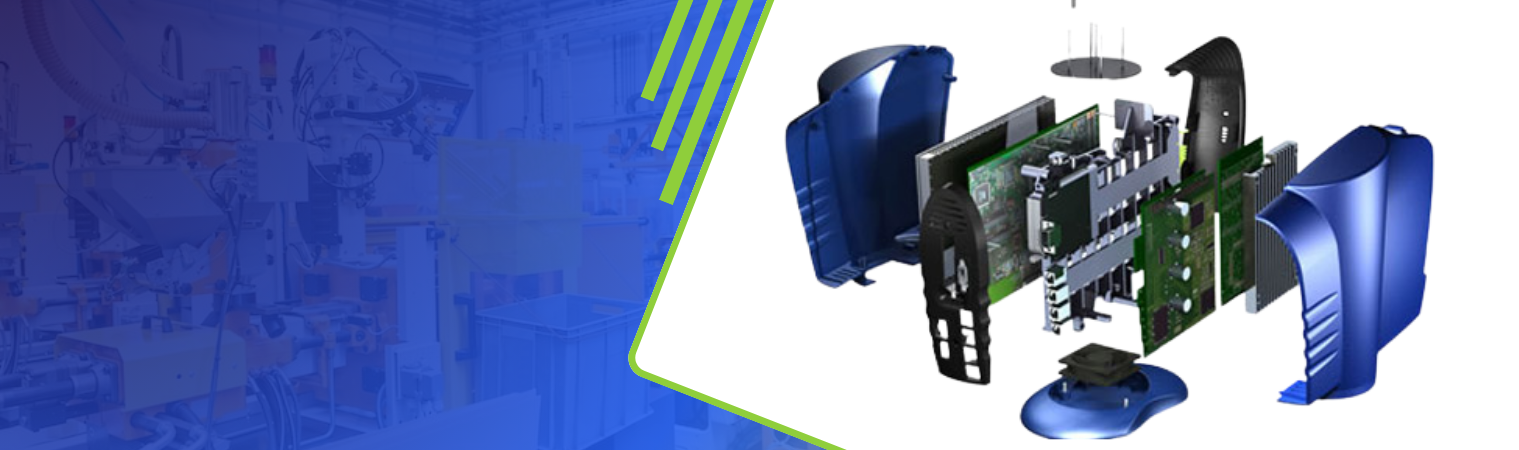

Range of Our Plastic Injection Molded Products for the Aerospace & Defence Industry

We specialize in a wide range of plastic parts to support many aerospace and defense needs, all made with our precision molds. Some of the parts we make include:

- Enclosures and housings

- Panels and inside structural pieces

- Brackets, clips, and connectors

- Covers and bezels for control panels

- Interior trim and other non-structural parts

All of these are non-critical aircraft components made exactly to your specifications, using high-quality materials and precise tooling to ensure they last and stay reliable.

Whether you need a simple enclosure or a more detailed molded part, our process is designed to give you consistent results that meet the quality, fit, and finish expected in aerospace and defense work.

Advanced Capabilities Supporting Aerospace & Defence Requirements

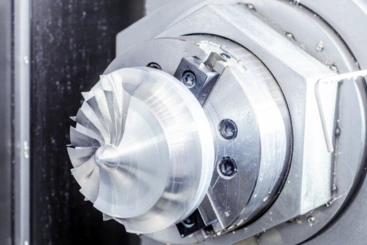

1. High-Precision Mold Engineering & Materials:

Our engineered aerospace plastic molds support tight tolerances, complex geometries, and multi-cavity production. We also work with high-performance thermoplastics such as PEEK, PEI, PPS, and reinforced composites ideal for aerospace plastic components.

2. Structural Optimization for Lightweight Design:

Using intelligent simulation tools, we are optimizing the wall thickness, location of gates, and cooling paths to make your lightweight molded parts function better and last longer.

3. Rapid Prototyping for Faster Validation:

Our quick prototypes let you test and review your custom aerospace plastic parts early, so you can feel confident before moving into full production.

4. Quality Assurance & Non-Critical Component Performance:

We carefully inspect and test every part, while our non-critical aircraft plastic parts are designed to be lightweight and make maintenance simpler.

5. End-to-End Manufacturing Support:

From concept to production, we ensure seamless execution for aerospace plastic components using engineered aerospace plastic molds.

If you need plastic parts for the aerospace or defence industry—whether lightweight components, custom molded pieces, or reliable non-critical aircraft parts—our team at Plastic Injection Molds is here to help. Reach out to us anytime, and let’s talk about how our aerospace molds can bring you the precision, durability, and efficiency your next project truly needs.

Call: +1 (647) 294-5240

Ready to See your Idea For Plastic Injection Molds

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.