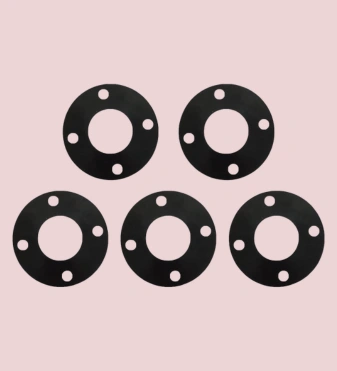

Rubber Gasket

Flexible & Durable

Leak-proof design

Chemical Resistance

Custom shapes & sizes

Easy installation

- Home

- Food Grade Rubber Gasket

Premium Food Grade Rubber Gasket for Safe & Reliable Sealing

The food and medical industry has to follow really careful rules about cleanliness and safety. Food-grade rubber gaskets are important components used in the food, beverage, and medical industries. These gaskets are typically designed to meet rigorous hygiene and safety standards, all while keeping the environment completely free from contamination.

At Custom Rubber Extrusion, we're experts at manufacturing non-toxic, odorless, FDA-approved rubber gaskets that fit the specific needs of industries where hygiene and safety are absolutely essential. Whether they're used in filling machines, bottling lines, or food processing equipment, these gaskets provide a secure air and watertight sealing, dependability, and long-lasting performance.

As one of the trusted food-grade rubber gasket manufacturers, we understand the requirements of food safety and thus we always prefer to select the harmless rubber compounds. Our gaskets are made from top-quality rubber that's approved under FDA, EU, and various other international guidelines for consumable products. These items can withstand high heat, pressure fluctuations, and repeated washing, which is why they are a reliable choice for keeping things safe and clean.

Role of Food Grade Rubber Gasket Maker

When you're choosing gasket makers of rubber food-grade, you should know that they have prioritized all food safety rules and regulations. Being the prominent food-grade rubber gasket maker, we make high-quality food-safe and hygienic gaskets by following both ISO and FDA standards. Here are the reasons why our customers choose us:

- Compliance with Standards: Our gaskets are made with FDA-compliant, BPA-free materials, ensuring they meet all the necessary health and safety guidelines.

- Customization Options: We can customize our gaskets to your precise requirements, adjusting everything from size and shape to hardness for a perfect fit.

- Reliability in Harsh Environments: Our gaskets are durable enough to withstand harsh food processing environments, ensuring resistance to oil, grease, and cleaning chemicals.

- Expert Support: Our team of experts provides complete design to production support to ensure you get the best possible fit and performance from your gasket.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Rubber Gaskets

Our Products

Reliable Food Grade Rubber Gasket Extrusion Process

Food-grade rubber gaskets are really important for keeping food and beverage products safe and hygienic within the processing system. As a food-grade rubber gasket extrusion manufacturer, we use advanced extrusion methods and premium rubber materials to manufacture rubber gaskets for hygienic sealing solutions for food and medical applications. The key importance of these rubber gaskets is:

- Temperature Resistance: They can handle a range of temperatures, from very cold (-60°C) to quite hot (+230°C), without breaking down.

- Superior Flexibility: These gaskets maintain their flexibility and create a tight seal, even when they're constantly being compressed or stretched.

- Custom Profiles: They can also be customised in a variety of shapes like round, square, U, P, D, etc, to match your equipment design.

- Chemical Resistance: These gaskets are durable enough to resist cracking, wear, and damage from various harmful chemical substances.

- Non-Toxic Material: Their non-stick and smooth surface doesn't let contaminants stick around, making it super easy to clean or sterilize.

Custom Solution for Food Grade Rubber Gaskets

Each industry has its own specific needs, and standard gaskets might not always be the correct fit. That's exactly why we make custom food-grade rubber gaskets designed specifically for food-processing and medical equipments. We provide a range of customization options, including:

- Size & Dimensions: We provide gaskets in small or large sizes to suit your specific equipment needs.

- Wall Thickness: We can optimise the wall thickness for greater flexibility or enhanced strength.

- Color Options: We also have various color options for you, from black, transparent, white, or a custom color to meet your visibility requirements.

- Material Hardness (Shore A): We provide both the softer material for increased flexibility and the harder material for improved durability.

- End Connections: We also provide various connection types, like flanged or clamped, or custom fittings to match your specifications.

Countries

Industries Served

Projects

Clients

Manufacturing Process of Industrial Food Grade Rubber Gasket

As an industrial food-grade rubber gasket company, we adhere to strict manufacturing process guidelines set by the food and medical industry, meaning every gasket is reliable and delivers the performance expected. Each rubber gasket is made using advanced extrusion techniques to ensure safe contact with food and medical products. Our process includes:

- Material Selection: We choose the best quality, safe, and non-toxic food-grade rubber compounds to meet FDA or equivalent standards.

- Molding or Extrusion: Our gaskets are made using precision molds or extrusion dies to achieve uniform shapes and sizes.

- Curing and Cooling: The rubber is carefully heated and cooled so that the rubber gets the right strength, elasticity, and stability.

- Trimming and Finishing: Any extra material, like flash and edges, is removed for smooth and clean surfaces.

- Inspection & Testing: Gaskets are then tested for dimensional accuracy, hardness, and visual quality to match design and tolerance requirements.

Why Choose Us?

As a reliable food-grade rubber gasket-making company, we provide safe and reliable rubber gasket products. We focus on non-toxic and certified food-grade materials, precise manufacturing methods, and strict quality control at every stage. We make durable gaskets that can easily withstand temperature changes, cleaning chemicals, substances, pressure, and constant use. Our gaskets also contribute to quieter and smoother machine operation by reducing noise and vibrations.

We provide both standard and custom rubber gaskets that prevent leaks, minimise downtime, and risk of contamination. With technical support and on-time delivery, we have become a reliable partner of our customers. We always make sure your equipment runs smoothly and your products remain safe and compliant.

Contact Us for Your Needs

Food-grade rubber gaskets are essential components that help keep products hygienic and safe, particularly in the food processing and medical industries. If you are looking for a food-grade rubber gasket supplier, then contact us to discuss your rubber gasket requirements. We are here to help you by delivering superior quality rubber gaskets that can be used in numerous applications where safety and cleanliness simply can’t be compromised. We custom-design our food-grade rubber gaskets to fit your specific industry needs, comply with food safety regulations, and promote optimal productivity.

Ready to See your Idea For Custom Rubber Below

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.