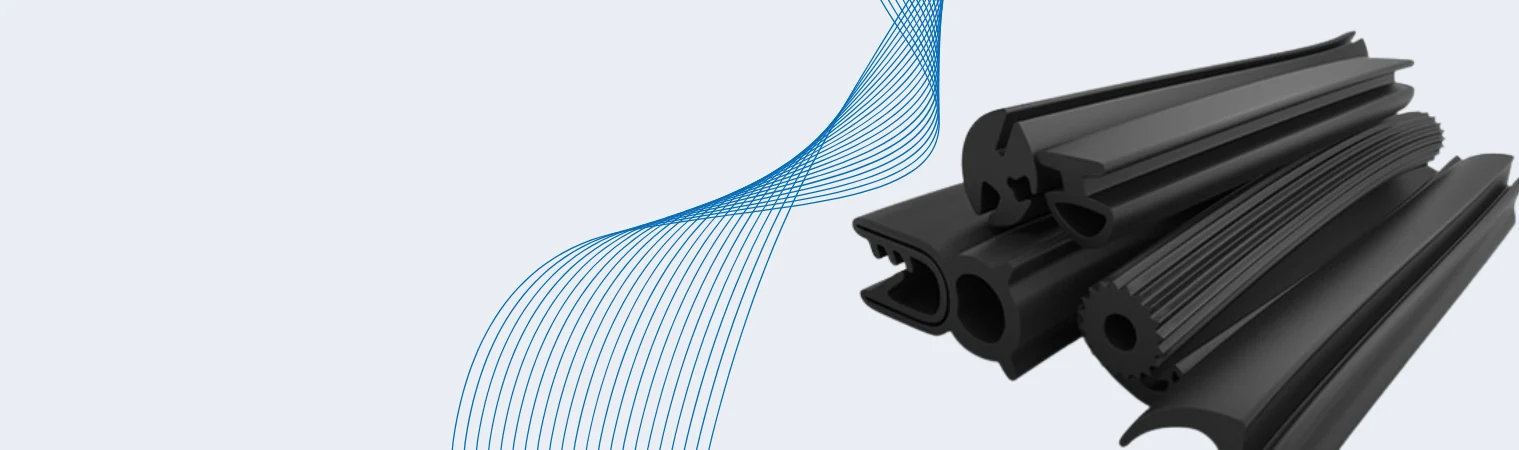

Rubber Extrusion Products

Flexible & Durable

Leak-proof design

Chemical Resistance

Custom shapes & sizes

Easy installation

- Home

- Rubber Extrusion Applications

Rubber Extrusion Applications and Manufacturing Solutions

Custom rubber extrusion applications play a crucial role in various industries, enabling the manufacture of strong, flexible, and precisely shaped rubber parts. At Custom Rubber Extrusion, we specialize in manufacturing high-quality, custom rubber extruded products designed to meet your specific application needs. From effectively sealing machinery to reducing vibration and noise and protecting equipment from external damage, our rubber extrusions are designed for high performance and long-lasting durability.

Whether you need simple profiles or complex custom shapes, our expertise ensures that products meet strict tolerances, dimensional accuracy, and functional requirements. We use state-of-the-art extrusion processes, top-quality raw materials, and cutting-edge manufacturing methods to serve the needs of different industries such as automotive, construction, marine, etc.

Our dedication to precision and the ability to customize mean we provide rubber extrusions that perform dependably, even under harsh environmental conditions. By prioritizing timely delivery and customer satisfaction, we guarantee that every project meets and surpasses the expectations of performance and quality.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Rubber Extrusion

Our Products

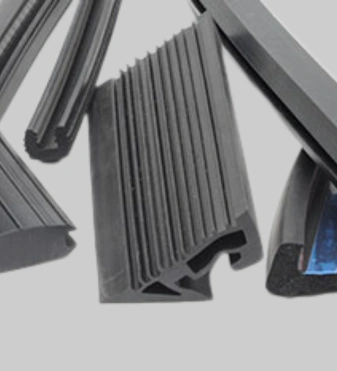

Understanding Rubber Extrusion Process

Rubber extrusion is a manufacturing process where raw, uncured rubber is pushed through a shaped opening called a die. This shapes the rubber into a specific form or profile, like seals, tubing, and various other rubber components. Extrusion is an excellent method because it provides design flexibility, uses material efficiently, and ensures that the final product has a uniform cross-sectional shape.

Once the rubber is pushed through the extrusion process, it's treated with vulcanization to boost its strength, flexibility, and temperature resistance. This method is useful for manufacturing components that are functional and can be custom-made to different sizes, colors, and hardness, making it the most suitable process for manufacturing rubber profiles.

Common Applications of Custom Rubber Extrusions

Custom Rubber Extrusions are customised rubber shapes made to fulfill specific design and performance needs. These provide flexibility, long-lasting performance, and accuracy for a wide range of industrial uses. They ensure dependable sealing, insulation, and protection in harsh conditions. Some major custom rubber extrusion applications include:

- Automotive Industry: Used for door seals, window channels, weatherstrips, and tubing to keep dust, water, and noise from getting inside the vehicle.

- Construction: Used for window glazing seals, expansion joints, waterproofing, and weatherproof door gaskets in construction projects.

- Marine: Rubber profiles are used for hatch seals, fendering, and edge protection to handle the harsh effects of saltwater and UV exposure.

- Electronics: Silicone extrusions are used as insulation, gaskets, and protective sleeves for wiring.

- Aerospace: High-performance rubber extrusions are utilized for reducing vibration and creating secure seals on important parts.

- HVAC and Plumbing: Rubber gaskets, tubes, and seals are essential to make sure systems are airtight and leak-proof.

Countries

Industries Served

Projects

Clients

Advantages of Rubber Extrusion Manufacturing

The industries that require both precision and top-notch performance all depend on the rubber extrusion manufacturing process. It delivers durable and resilient products that are perfectly suited to the specific needs and operating environments. The advantages of manufacturing through extrusion are:

- Design Flexibility: This process is useful for making intricate profiles or shapes in continuous lengths, all customised to specific design requirements.

- Material Selection: Materials like EPDM, Neoprene, Nitrile, and Silicone are selected based on performance needs.

- Consistent Quality: Extrusion ensures each piece is of high quality and with a uniform size and shape cross-section.

- Durability: Rubber extrusions are strong enough to handle tough environmental conditions, harsh chemicals, and high temperatures.

- Cost Efficiency: Because extrusion minimizes material waste, it's a more economical choice for manufacturing in large quantities.

Your Trusted Rubber Extrusion Makers

As one of the leading rubber extrusion makers, we design and manufacture extruded profiles according to particular application specifications. We provide comprehensive assistance throughout the entire process, from the right material selection and tooling design to the final stages of production and rigorous quality assurance. To guarantee consistent and precise results in every profile, we use state-of-the-art extrusion equipment, curing systems, and testing facilities

Beyond just making rubber extrusions, we also focus on value-added services like cutting, joining, adding adhesive, and co-extrusion of different materials for more complicated uses. That's why every extruded profile is carefully checked to verify its quality, dimensional accuracy, hardness, strength, and smoothness. This quality check guarantees the final product will perform reliably for its intended application.

Benefits of Choosing Rubber Extrusion Companies

Rubber extrusion companies play a key role in making custom-designed profiles for different types of applications. We use precision tooling and manufacturing processes to develop extruded rubber profiles with tight tolerances, from U-shaped channels and D-shaped profiles to tubing and edge trims. There are numerous benefits of selecting rubber extrusion companies:

- Customization Capabilities: We can create profiles, adjust hardness, and even do co-extrusion, all customised to match your specific design needs.

- Advanced Technology: We use modern extrusion machinery and precision tooling to achieve smooth finishes and consistent quality in every profile.

- Quality Control: We do thorough inspections and tests to ensure perfect sizing, resistance to compression, and long-lasting durability.

- Design Support: We provide design assistance, make CAD models, and build prototypes to ensure accurate fit and function.

- Timely Delivery: We manage our production efficiently to guarantee your orders arrive on schedule.

- Customer Service: We offer clear communication, regular progress updates, and reliable after-sales support to ensure your complete satisfaction.

Why Choose Us?

As one of the trusted rubber extrusion manufacturers, we're dedicated to providing you with top-notch extruded products and expert assistance every step of the way. We make both common and custom profiles or shapes in various sizes, colors, and materials. Each product is manufactured to strict tolerances using precision manufacturing techniques. This guarantees excellent dimensional accuracy and reliable performance every time.

We follow ISO-standard procedures, ensuring every item is of high quality from start to finish. From the initial prototype development right through final production, we aim to go above and beyond our clients' expectations. We're really proud of our ability to provide dependable, affordable, and specially designed rubber solutions to fulfill your specific requirements.

Contact Us for Your Needs

Rubber extrusion is the most preferred manufacturing method for industries that demand precision, durability, and flexibility. We provide dependable custom solutions to boost the durability and product performance. We blend our technical skill and modern production methods to manufacture outstanding rubber profiles designed specifically for our customers' needs. If you're searching for reliable rubber extrusion manufacturers that can provide custom, high-quality rubber profiles, then reach out to us today to discuss your needs. We will provide excellent rubber solutions for your specific application.

Ready to See your Idea For Custom Rubber Below

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.