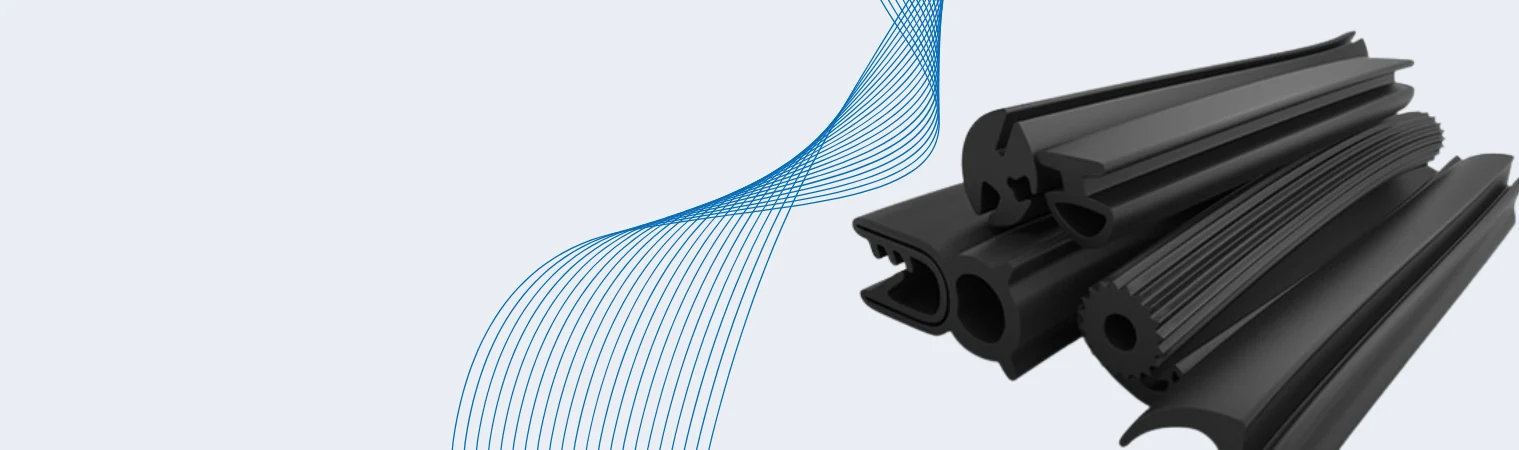

Rubber Extrusion Products

Flexible & Durable

Leak-proof design

Chemical Resistance

Custom shapes & sizes

Easy installation

- Home

- Rubber Extrusion Profile

Custom Rubber Extrusion Profiles for Industrial Applications

Rubber extrusion profiles are vital components used for sealing, insulation, noise, and vibration control in numerous industrial applications. These profiles are made with premium rubber materials that perfectly fit the specific shapes and dimensions. With our skills and expertise, we at Custom Rubber Extrusion make durable and flexible extruded rubber profiles of the highest quality.

We use state-of-the-art- art modern extrusion methods, so that our rubber profiles can perform well even under harsh environmental conditions and also have a great service life. We provide various types of extruded rubber products such as seals, gaskets, hoses, and others. Regardless of whether you need to have a simple D-section or a radical custom design, we know how to deliver exactly what your project calls for.

We are also dedicated to strict quality control as well as timely delivery. Moreover, our proficiency in extrusion manufacturing allows us to be a reliable partner for any type of rubber or silicone extruded profile applications.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Rubber Extrusion

Our Products

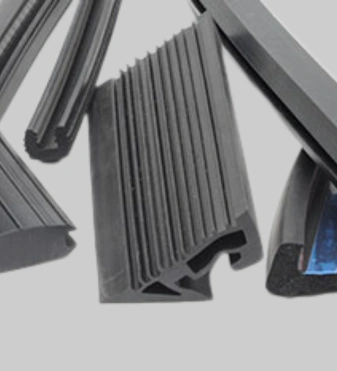

What Are Extruded Rubber Profiles?

Extruded rubber profiles are basically long, continuous pieces of rubber made by pushing raw, uncured rubber material through a mold (called a die). After this process, the rubber undergoes a curing process (vulcanization) to give it its final useful characteristics, such as durability, flexibility, and ability to withstand various environmental conditions. Such profiles have different shapes for example tubes, channels, seals, or strips. These products find their application in various sectors like automotive, construction, marine, and electrical, where they help in sealing, cushioning, and reducing the vibration.

Typical shapes are:

- D-section and P-section profiles

- U-channels and T-sections

- Bulb seals and edge trims

- Custom-designed profiles for particular uses

Advantages of Custom Extruded Rubber Profiles

Every project is different from each other, so we provide rubber profiles made just for you. Custom extruded rubber profiles are used for different purposes, such as door seals, window gaskets, and electrical enclosures. They keep out dust, moisture, and even cut down on vibration. When you go with a profile that’s designed specifically for your needs and made by extrusion, you get some real benefits:

- Customised Fit: These are made to match your exact size and performance needs.

- Material Flexibility: They can be made with a variety of materials like EPDM, Nitrile, Neoprene, Natural Rubber, or Silicone.

- Durability: They remain fairly resistant to weather, UV rays, chemicals, and temperature changes.

- Versatile Applications: The use of these is spread over different industries, such as the automobile, building, electrical, marine, and manufacturing sectors.

Countries

Industries Served

Projects

Clients

Your Trusted Rubber Profile Manufacturer

We position ourselves as a technically expert company that combines skill with high production standards in quality, among the foremost rubber profile manufacturers. To keep our quality up to standard, we use state-of-the-art machines for molding, heating, and quality control. By this means, we can promise precision with every piece that we manufacture. These are the reasons our customers choose to work with us:

- Extensive Industry Experience: With experience of the diverse needs across different industries, we provide reliable rubber extrusion solutions perfectly suited for any application.

- Advanced Extrusion Technology: We use the latest production methods, ensuring consistent quality, precise dimensions, and smooth surfaces for our rubber profiles.

- Strict Quality Control: Every single product goes through careful testing to make sure it meets international quality and precision standards.

- Timely Delivery and Support: Our smooth production and logistics systems guarantee on-time delivery and dedicated customer support.

Our Rubber Extrusion Manufacturing Process

As a reliable rubber extrusion parts manufacturer, we make precisely sized seals, gaskets, tubes, or edge trims with a smooth surface finish and long-lasting durability. We use state-of-the-art extrusion manufacturing techniques to ensure each part has a consistent size and reliable quality that meets or exceeds industry standards. Our manufacturing process includes:

- Material Selection: We select the right material that fits both the environmental conditions and application requirements.

- Die Design: Our extrusion dies are custom-designed for making your specific cross-section shape.

- Extrusion: We push the rubber material through the die to create the final profile shape.

- Curing/Vulcanization: The extruded rubber is heated to make it stronger and more flexible.

- Cutting & Finishing: Then the rubber is trimmed to the right length, and if needed, adhesives or surface treatments are applied.

- Quality Inspection: At last, we check the shape & size, hardness, and surface finish for precision.

Benefits of High Temperature Silicone Rubber Profile

We use different kinds of rubber, but silicone is one of the preferred materials because it’s so versatile and performs so well. Silicone rubber profiles are known for their ability to withstand extreme temperatures, UV rays, and weather resistance, making them ideal for outdoor, electrical, and even food-grade applications. The benefits of these rubber profiles are:

- It stays flexible up to a broad temperature range from -60°C up to +230°C.

- It withstands exceptionally well against ozone, UV rays, and various weather conditions.

- It also provides excellent electrical insulation for electronic and lighting components.

- Being chemically inert, it's completely non-toxic and safe for food and medical applications.

- It can be made clear, translucent, or in a variety of colors, sizes, shapes, and designs to suit your specific needs.

Contact Us for Your Needs

We strive to supply high-quality extruded rubber products that can be your reliable source of excellent performance and long-lasting quality. We blend cutting-edge tech with a deep understanding of rubber extrusion, so you get profiles with spot-on dimensions every time. If you require specific seals, insulation, or protective solutions, we are capable of designing and manufacturing extruded parts tailored to precisely match your needs. For strong, reliable extruded rubber profiles, reach out to us today to discuss your project requirements and get expert guidance.

Ready to See your Idea For Custom Rubber Below

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.