Rubber Gaskets

Weatherproof

UV Resistant

Long Durability

Premium Quality

High Performance

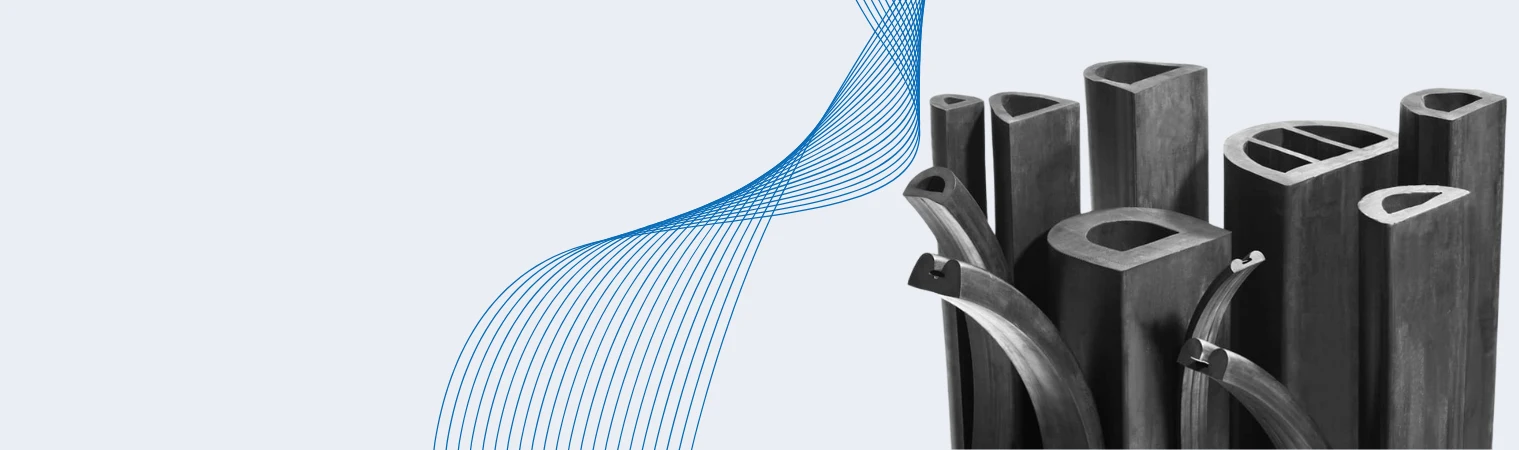

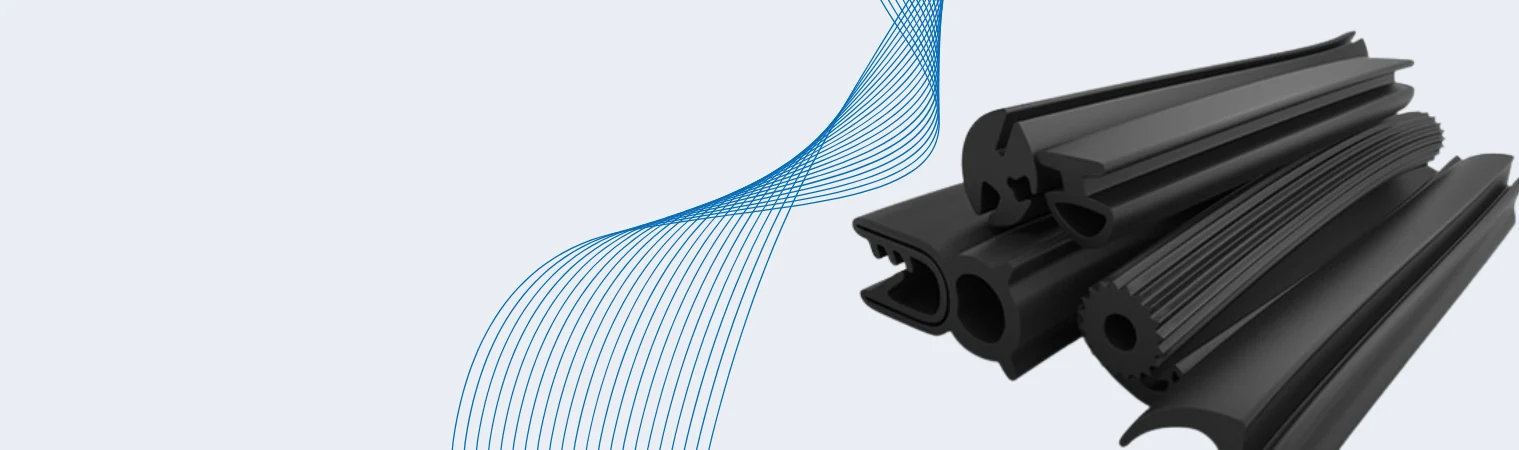

Rubber Profiles

Custom Designs

Precision Fit

Smooth Edges

Longer service life

Accurate Dimensions

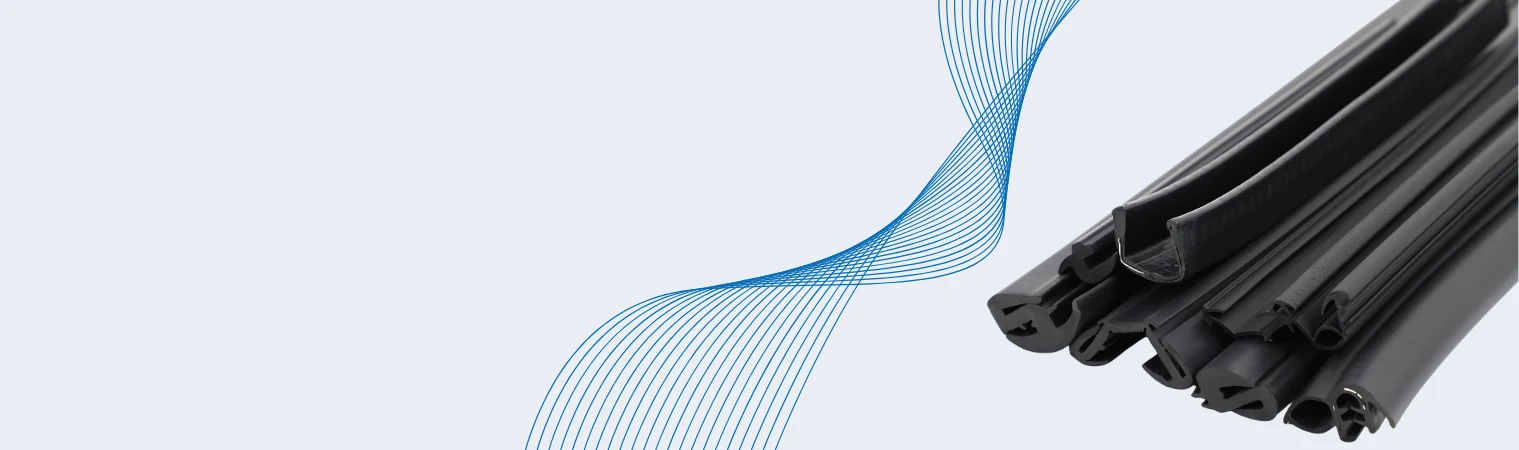

Rubber Seals

Heat Resistant

Long Durability

Protective Sealing

High Compression

Customizable sizes

Rubber Channel

High Elasticity

Reliable Sealing

Custom Sizes

Weather Resistant

Superior Performance

Rubber Extrusions

Perfect Fit

Anti-Vibration

UV Resistant

High Precision

Easy Installation

EPDM Extrusion

High Durability

Smooth Finish

Superior Quality

Custom Shapes

Versatile Use

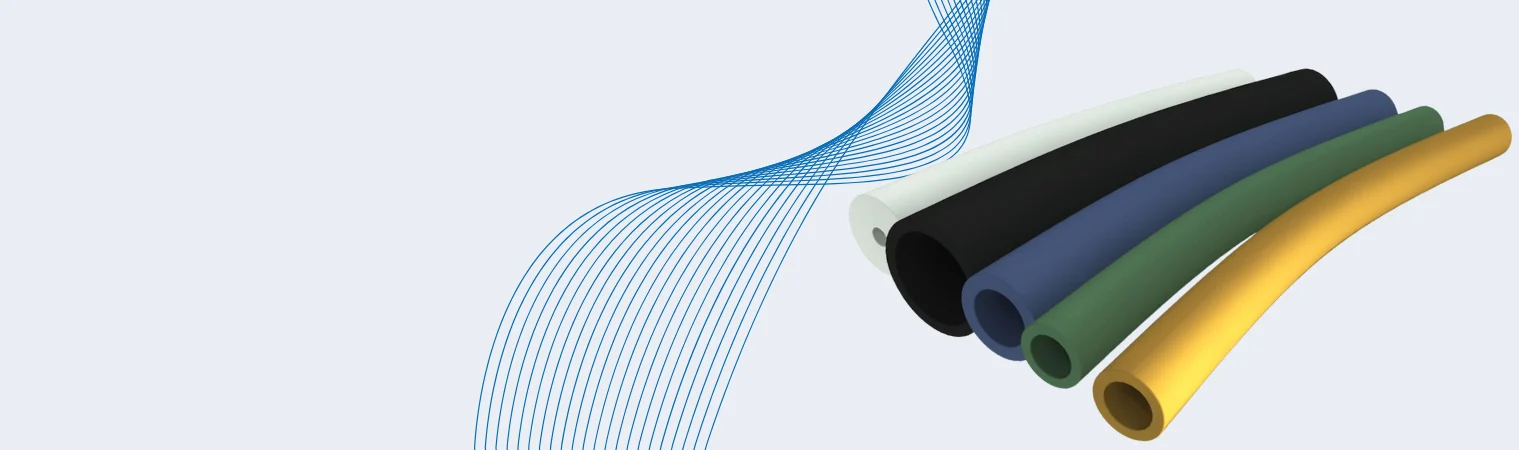

Tubing & Hoses

Smooth Flow

High resilience

Custom Lengths

Leak Prevention

Chemical resistant

- Home

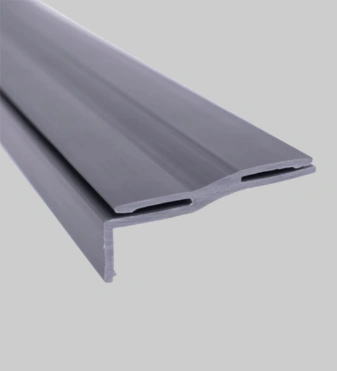

- Dual Hardness Rubber Extrusion

Custom Dual Hardness Rubber Solutions for Sealing and Insulation

Dual hardness rubber extrusion is a process in which two different rubber compounds, each with a different hardness (measured in Shore A), are co-extruded into a single, continuous profile. This technology is useful when a single-hardness rubber profile cannot meet all performance requirements, such as in high-pressure sealing, dynamic movement, or heavy-load applications.

At Custom Rubber Extrusion, we use modern extrusion processes and precise tooling to produce complex shapes with consistent bonding between the soft and hard layers. This results in durable, long-lasting parts that improve equipment reliability across industries like automotive, industrial machinery, construction, and more. These components absorb vibration, seal effectively, and resist wear in harsh industrial environments.

We provide solutions that are tailored to each specific application, rather than relying on standard profiles that may not perform optimally. We develop profiles that meet exact dimensional and functional requirements for industrial applications. From complex sealing systems to structural supports, our dual hardness rubber extrusion allows you to enhance durability and improve product quality in one integrated component.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

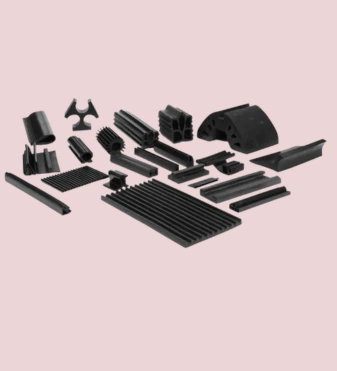

Other Extruded Products

Our Products

Your Trusted Custom Dual Hardness Rubber Extrusion Manufacturer

As a leading custom dual hardness rubber extrusion manufacturer, we work closely with you to design, develop, and deliver custom profiles that match your exact application, tolerance, and durability needs. Here are the reasons why our customers choose us:

1. Application-Based Design

We start with your drawing, sample, or idea to understand:

- Operating temperature

- Media exposure (water, oil, chemicals, UV)

- Compression and movement

2. Tooling and Die Development

We design and manufacture custom extrusion dies to create custom-engineered Hardness Rubber Profiles that match your cross-sectional design. Precise tooling ensures:

- Correct dimensions and tolerances

- Stable bonding between soft and hard sections

- Repeatable quality in mass production

3. Material Selection & Dual Durometer Matching

Different durometer combinations to meet the exact sealing force, compression set, and mechanical strength your application needs – for example:

- 60–70 Shore A hard base + 30–40 Shore A soft sealing lip

- 80 Shore A hard carrier + 50 Shore A flexible fin

Key Benefits of Industrial Dual Hardness Rubber Seals & Gaskets

Dual hardness technology is widely used for industrial dual hardness rubber seals & gaskets in various sectors. These components help reduce maintenance issues, improve safety, and ensure better protection against dust, water, air, and noise. The key benefits are:

- Secure mounting: Hard section clips or locks into metal, plastic, or glass

- Superior sealing: Soft section follows surface irregularities for leak-tight performance.

- Reduced vibration and noise: Soft rubber absorbs noise and movement.

- Long service-life: Suitable materials resist ozone, UV, chemicals, and temperature swings.

Countries

Industries Served

Projects

Clients

Custom Solutions for Dual Hardness Rubber Profiles

Every project is different, so we deliver custom-engineered dual hardness rubber Profiles tailored to your specifications. Our goal is to produce custom-engineered Hardness Rubber Profiles that integrate perfectly into your product design and meet your performance targets.

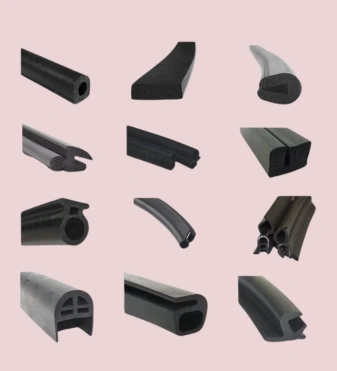

- Bulb seals with carrier: A soft bulb for sealing integrated with a rigid or semi-rigid carrier for clipping.

- U-channel with flexible lip: Hard U-channel to grip edge, with soft fin for sealing or wiping.

- T-profiles and P-profiles: Combined geometries to meet unique sealing and mounting needs.

- Corner-moulded or cut-to-length: Profiles can be made in coils, straight lengths, mitre-cut, or joined as frames.

Manufacturing Process of High-Performance Dual Hardness Rubber Components

We follow a controlled, step-by-step manufacturing process to produce High Performance Dual Hardness Rubber Components that deliver reliable sealing, support, and long-term durability. Each stage is carefully monitored to ensure strong bonding between the soft and hard sections and consistent quality in every batch.

- Material & Durometer Selection: Suitable rubber compounds and hardness combinations are chosen to achieve the required flexibility, strength, and compression behaviour.

- Co-Extrusion: Two rubber compounds are co-extruded simultaneously, forming a single profile with stable bonding between the hard and soft sections.

- Curing & Vulcanization: The extruded profiles pass through controlled curing or vulcanization to develop full mechanical properties and long-term performance.

- Cutting & Finishing: Profiles are cut to length, joined, punched, or processed as needed to meet your final part requirements.

- Inspection & Quality Control: Dimensions, hardness, bonding strength, and visual quality are checked to ensure every component meets your specifications.

Why Choose Us?

Choosing us as your custom dual hardness rubber extrusion suppliers means partnering with a team that truly understands both engineering and real-world application needs. We combine strong technical knowledge, precision tooling, and carefully matched dual durometer materials to deliver profiles that fit right, seal effectively, and last longer in demanding environments.

From initial design and material selection to co-extrusion and final inspection, every step is controlled to ensure consistent bonding between soft and hard sections. We support you with flexible order quantities, quick response, and guidance, helping you improve overall product quality. Our goal is not just to supply extrusions, but to become your trusted long-term partner for dual hardness rubber solutions.

Contact Us for Your Needs

If you are looking for a reliable manufacturer of custom dual hardness rubber extruded seals, gaskets, or engineered profiles, we are ready to help. Share your drawings, samples, or application details, and our team will guide you with the right material, hardness combination, and profile design. Contact us today to discuss your requirements for dual hardness rubber components. Whether you need prototypes or full-scale production, we offer responsive support and timely deliveries.

Ready to See your Idea For Custom Rubber Below

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.