Fastest Delivery and Low MOQ with Money Back Guarantee...

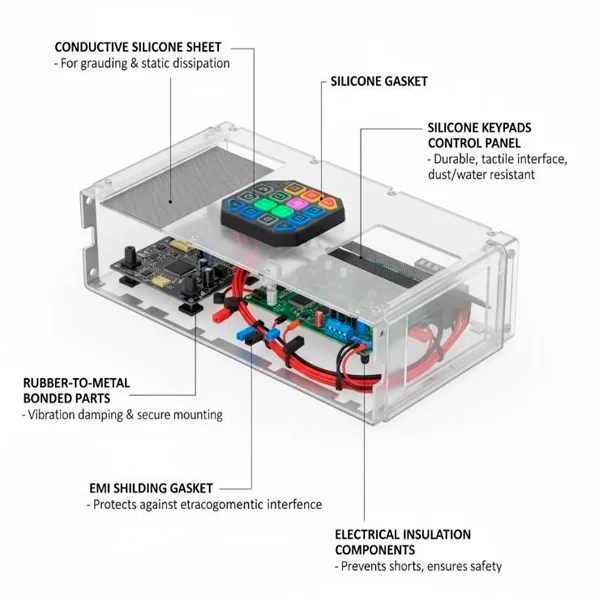

Rubber Silicone Molds designs and assembles high precision silicone seals, rubber gaskets, and silicone rubber molds that are specially designated for the electronics industry. These products help in keeping electronic circuits highly protected, improving performance, and ensuring them a durable life. With this level of experience in silicone molding and manufacturing systems taken to a whole new level, we develop reliable silicone rubber parts for electronics with integrity even in the most adverse operating conditions.

Make Appointment

We have spent over a decade enhancing our skills as one of the most reliable electronic sealing gasket manufacturers.

Our engineers work closely with customers to provide custom-designed silicone molds and sealing components for their specific product requirements. From EMI-resistant gaskets to heat-stable silicone seals, all our products are manufactured with an emphasis on precision and durability.

We ensure that all our molds and components are manufactured in accordance with international quality and safety standards.

Our mission is very simple: to make the electronic components more reliable and efficient through new-age silicone molding technologies.

With over a decade in the industry, we have revolutionized the perception of precision silicone molding for electronics by integrating innovation in design and performance materials into the approach.

Here’s how we do it:

Along with providing silicone and rubber components, we also manufacture smarter and more secure systems, striking the right balance of functionalities to last more.

Uses modern compression, transfer, and injection molding techniques for accurate results.

The design of every component is customized as per the customer's requirements and application standards.

Has different types of silicone, EPDM, and other rubbers with excellent resistance properties.

The design of every component is customized as per the customer's requirements and application standards.

Our rubber insulation components for electronics and EMI shielding silicone components are synonymous with reliability and long service. Our products lead to better efficiency and endurance in machines.

Major Advantages:

Rubber Silicone Molds aims to bring components into reality that go beyond utility in terms of enhancing the reliability and attractiveness of the end products.

A complete portfolio of components based on silicone and rubber, for every application in electronics and electricals, includes:

Each product is crafted with utmost precision by advanced molding techniques to ensure consistent performance, combined with long life.

Rubber Silicone Molds offers Manufacturing and Production of Custom Rubber Molded Products, Silicone Molds, Rubber Extrusions and other Industrial, Food and Medical Grade Products!

Silicone has changed the game in the field of electronics. With a great number of properties, such as being nonconductor and flexible and even heat-stable is perfect for making safe and reliable sealing systems.

As silicone keypad molding manufacturers, we make the keypads for remote controls, medical devices, and industrial electronics. These qualities combined give a smooth and responsive feel, while they also resist wear, ensuring that silicone keypads can be used frequently.

As electronic sealing gaskets manufacturers, we make sure that everything we manufacture within the U.S will provide airtight protection to sensitive electronics. Using our expertise in materials, we help companies create devices that have a longer lifespan and perform better in adverse environments.

We are continuously working on innovations to propel electronic devices forward. Our R&D team explores improved formulations and techniques to provide better EMI shielding silicone components for more significant signal security and rubber insulation components for electronics that can withstand a chamber of miniaturization and considerable heating.

Partnering with electronic manufacturers, we make custom rubber parts for electrical devices that fit the changes of evolving designs-from smart gadgets to power systems. Every project we get is a chance to raise the bar on performance, efficiency, and sustainability

137-1140 Burnhamthorpe Rd. W | Mississauga ON L5C 0A3 | Canada

© RUBBER SILICONE MOLDS. All Rights Reserved.