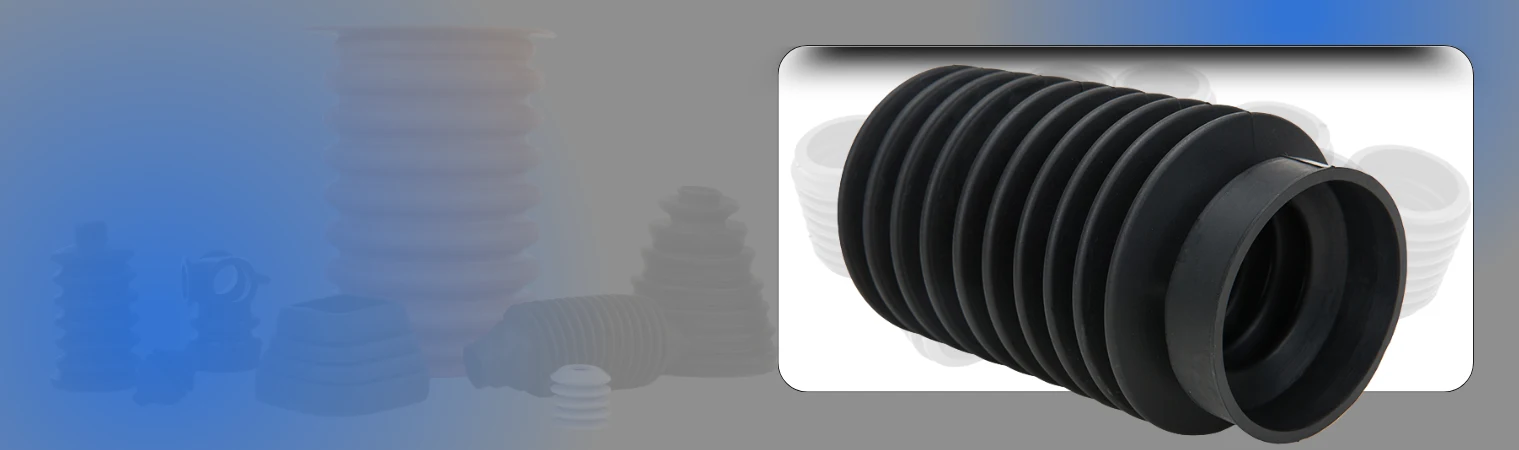

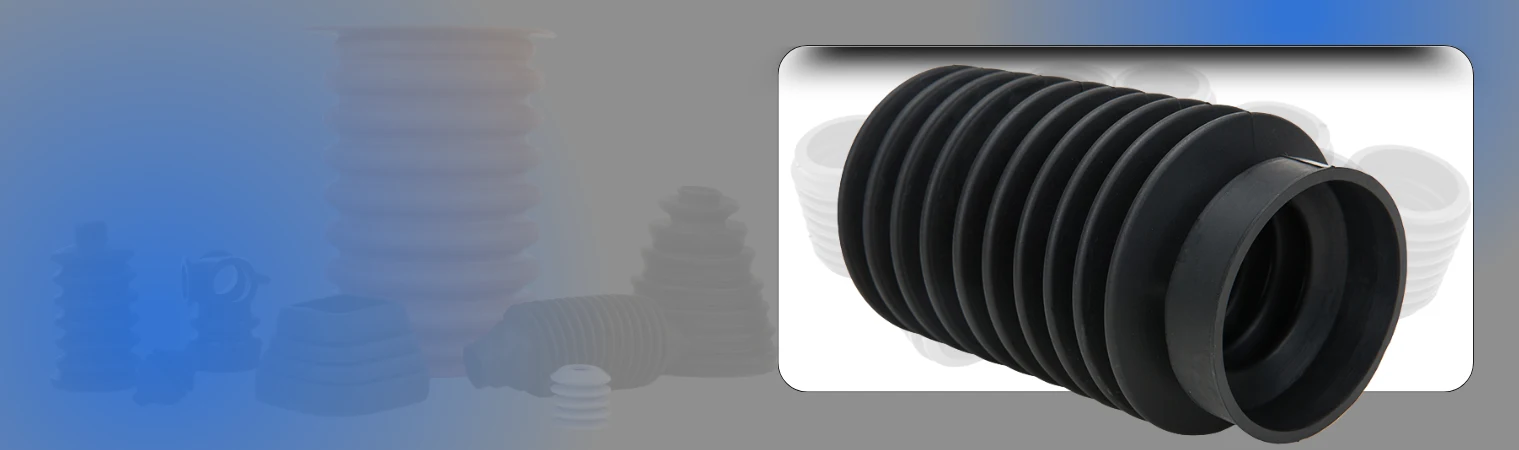

Custom Rubber and

Silicone Bellows

Low MOQ

Non Sticky

Total Design Support

Lab Tested Food Safe

Fastest Delivery and Low MOQ with Money Back Guarantee...

Custom Rubber and

Silicone Bellows

Low MOQ

Non Sticky

Total Design Support

Lab Tested Food Safe

Join us whenever you are looking for the finest condition of flexible bellows and we are here to serve you right. We are here to provide you with the finest range of the silicone based rubber bellows, along with some of the other options as well. We have segmented these categories under industrial rubber bellows and have served so many industries already with this form of service over here for sure. It is always mandatory for you to catch up with the best teams for help in this regard.

Yes, we are able to offer you with the best option when the matter revolves around the small rubber bellows practices. On the other hand, from c type bellows to the industrial Teflon bellows, we have so many other options for you as well.

3D printing is an innovative technology revolutionizing the manufacturing industry, including rubber bellow manufacturing. 3D printing allows for creation of complex designs and shapes that were previously impossible to manufacture. This technology enables us, the silicone bellows manufacturers, to create bellows with intricate shapes and features, with high accuracy and repeatability.

Injection molding is a popular technique used in rubber bellows manufacturing. Our this technique involves injecting molten rubber into a mold, which is then cooled and solidified into the desired shape. Injection molding allows for producing high volumes of bellows with consistent quality and accuracy. This technique of Rubber Silicone Molds is particularly suitable for manufacturing complex and intricate bellows shapes.

Composite materials are made by combining two or more elements with various characteristics.. We use composite materials in molded rubber bellows manufacturing to enhance the bellows' mechanical, thermal, and chemical properties. For example, molded bellows made with composite materials can have higher temperatures and chemical resistance than standard rubber bellows.

We, Rubber Silicone Molds, the Molded bellows manufacturer, is constantly exploring new materials to improve the performance of their products. Advanced materials such as fluoroelastomers and silicone have better resistance to high temperatures, chemicals, and UV light. These materials are widely used in high-performance aerospace, defense, and medical applications. We strive to ensure our clients receive the best possible product and are always looking for new ways to improve our manufacturing process.

Automation is another innovative technology that is transforming the rubber bellows manufacturing industry. Automated manufacturing systems can produce high volumes of bellows with consistent quality and accuracy. This technology also improves efficiency and reduces production time and costs.

Now, you might be wondering why people are more towards our side when they have others dealing with flexible rubber bellows as well. The best thing about our company, which sets us apart from others, is timely delivery of our items.

So, you have been making plans to rely on us for the custom bellows. Before any of that, we would want you to learn more about the items and the features involved in the same section.

The rubber bellows manufacturing industry constantly evolves, with new technologies and techniques emerging daily. Silicone bellows manufacturers willing to invest in innovative technologies and techniques are better equipped to meet the demands of their customers and stay competitive in the market. By staying up-to-date with the latest trends and innovations, manufacturers can improve their products' quality, performance, and efficiency.

137-1140 Burnhamthorpe Rd. W | Mississauga ON L5C 0A3 | Canada

© RUBBER SILICONE MOLDS. All Rights Reserved.