Custom Designs & Quality

Rubber Molded Products

Low MOQ

Non Sticky

Total Design Support

Lab Tested Food Safe

Fastest Delivery and Low MOQ with Money Back Guarantee...

Custom Designs & Quality

Rubber Molded Products

Low MOQ

Non Sticky

Total Design Support

Lab Tested Food Safe

Do you even know why Rubber Molds are widely popular among the masses? You will surely understand its value when you delve deep into the market and the manufacturing houses. Most of the constructed materials are made using the molds out of rubber. These molds are widely used for concrete, plaster and cement stone. So, if you are associated with any of these industries then these molds are just perfect for you. You can get these reliable molds from us and we will not leave your side unless you are happy with the items we got for you.

We just don’t want to be any company selling these rubber molds but want to be your best ever rubber moulding company that you can possibly think of. For that, we are able to work hard and extra with the finest possible molding help.

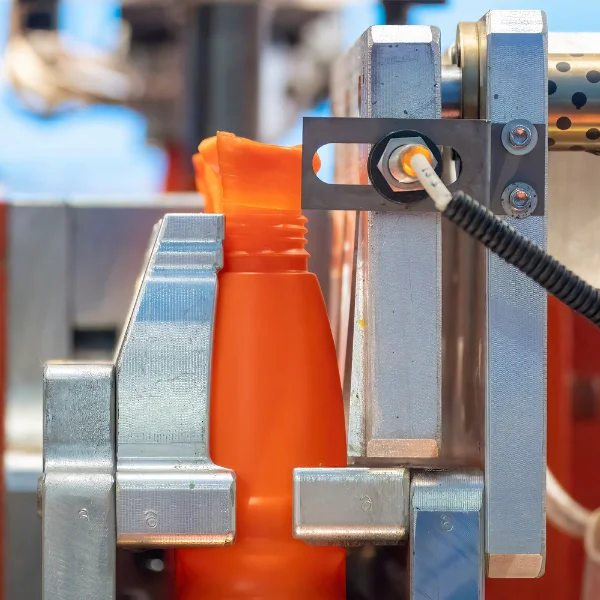

When purchasing gaskets, gaskets, hoses, tubes, and other mechanical components, the benefits of our custom rubber molding cannot be ignored. Customized molded parts are manufactured in a molding process. For example, injection molding is often used to create custom-molded parts. In injection molding, heated material is injected into a mold cavity. As it cools, the material hardens and forms a new part. What is the exact reason why you should choose custom-molded parts?

Strength of custom rubber molding

Custom molded parts are strong. It can withstand harsh temperatures and extreme environments without damage or deterioration. Finally, most custom-molded parts are made from material that is preheated before being injected into the mold cavity. As the material cools, rubber custom molded products become stronger. You can find custom-molded parts made from a variety of materials, but they are all extremely strong.

Corrosion resistance

Corrosion is usually not an issue with custom-molded parts. As a rule, they do not contain any corrosive materials. As a result, custom-molded parts last longer, even when used in wet or damp environments. The corrosion resistance of custom-molded parts makes them popular as mechanical parts.

Elasticity

Specially molded parts are elastic. Most of them are made of materials such as rubber, plastic, or polymer. All these materials are elastic. Due to their elastic properties, Rubber part's manufacturer molded parts are ideal for sealing applications. This means that it deforms when pressure is applied and returns to its original shape when the pressure is released. Custom-made gaskets, O-rings, and other seals can prevent leaks in the machines in which they are used.

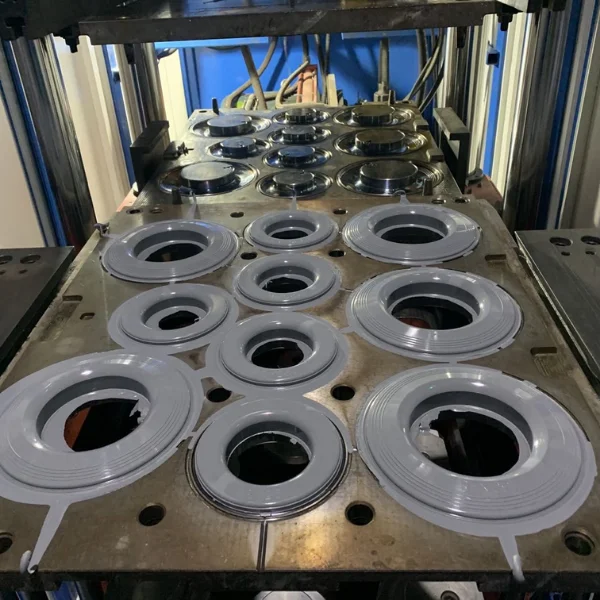

Accommodates a variety of shapes and sizes

You can order custom-molded components in lots of shapes and sizes. The shape and size of the custom-molded part will of course depend on the mold. To create a part of a particular shape and size, manufacturing companies use corresponding molds of the same shape and size.

We have been working as the best ever and reputed rubber mold company for our clients for years now. So, the next time you want some customized rubber molds for your industrial use, we will be there to help you big time.

We are always super pumped to address new mechanism to make our molding process a lot easier and helpful for the clients as well. Our services are well-associated with the liquid rubber mold making procedure as well, which will work out in the way you could have asked for it. You can easily start your own high profit based manufactured stone business by getting the rubber molds from us. That’s what makes us a reliable name for you to choose and work out with over here now.

Low cost

Another advantage of custom rubber molding parts is the price. There are other ways to make parts. However, it requires more time, effort, and energy than custom molding. Manufacturers can produce custom-shaped parts more quickly and efficiently. Therefore, they pass these savings on to their customers in the form of lower prices.

137-1140 Burnhamthorpe Rd. W | Mississauga ON L5C 0A3 | Canada

© RUBBER SILICONE MOLDS. All Rights Reserved.