Low MOQ

Non Sticky

Total Design Support

Lab Tested Food Safe

Aerospace rubber mold parts come in forms of seals and gaskets, vibration dampers and insulation components

Manufacturers obtain high dimensional accuracy and consistency using high-level molding techniques

Silicone is among the most desirable materials in the electronics industry since it can withstand high temperatures

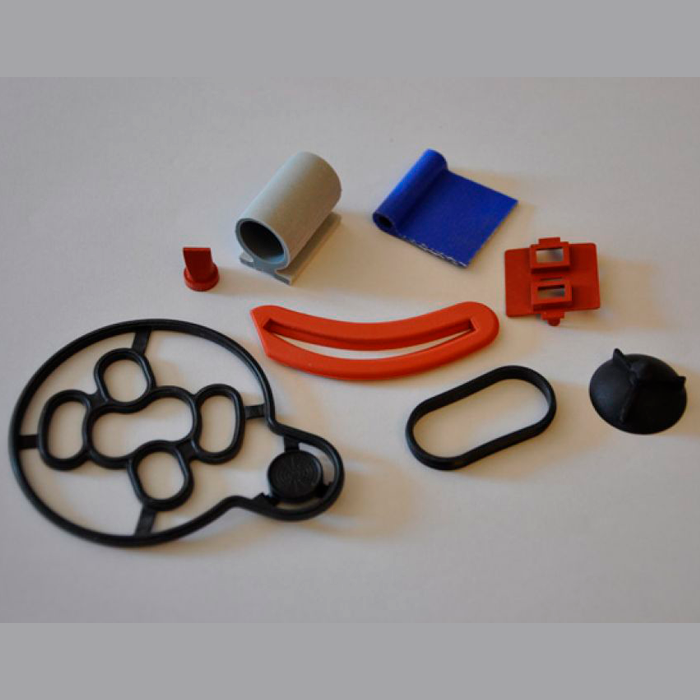

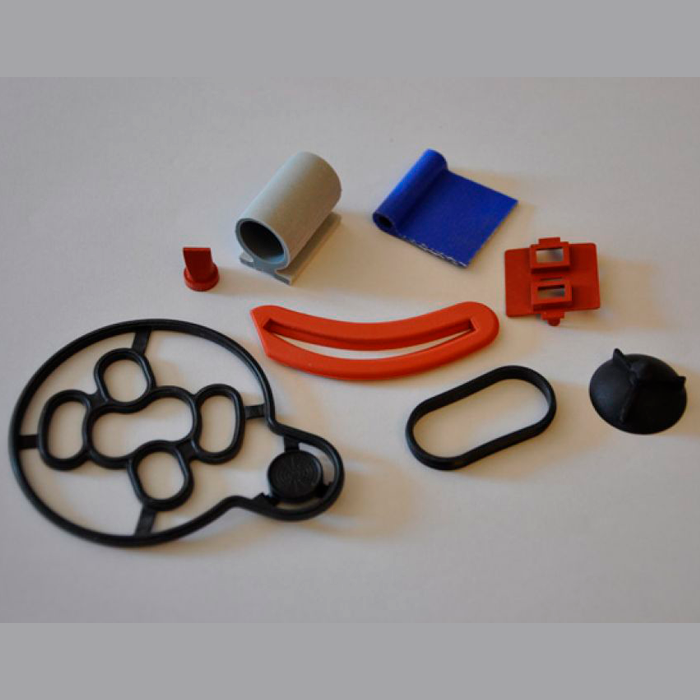

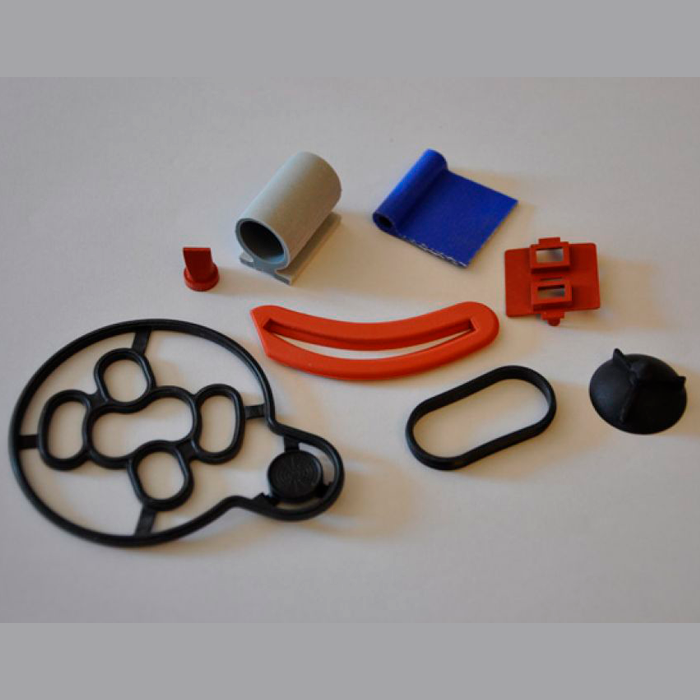

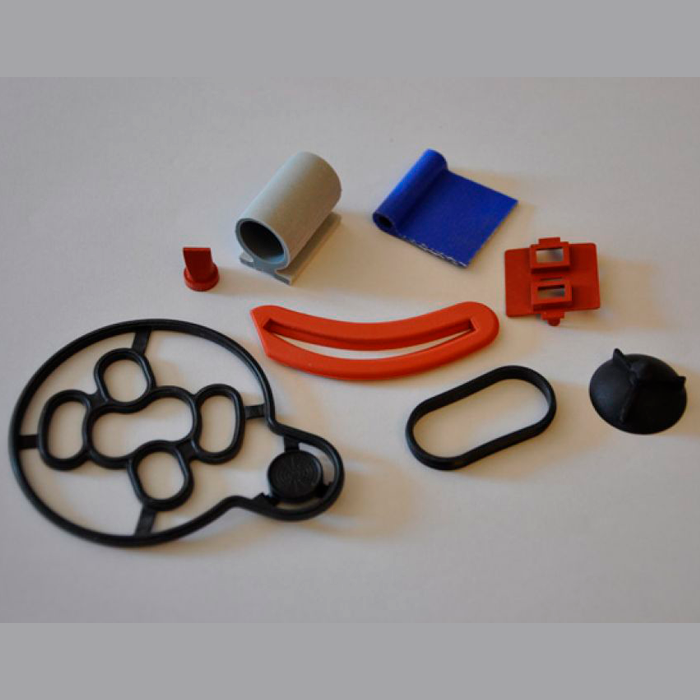

The advantages of silicone in the consumer goods sector include the flexibility, ability to withstand wear and tear, non-toxicity

There are so many industrial uses of rubber grommets these days. Available in so many shapes and sizes, you can get your hands on the ones you want. Right from the 1 inch rubber grommet to the LED 6 inches one, the market houses some of the best grommets you could have ever asked for. Some companies are further manufacturing customized grommets for their users, just to make them happy. In case, you are aiming for one such company then you have come to the right spot. We are proud to serve you with small and large rubber grommets to cover your use, just like you have wanted it.

Just like the sizes of the rubber grommets, we take a special note towards the shape of these items as well. So, we have already manufactured some of the best oval shaped rubber grommets in this regard. In case, you are aiming for oval rubber grommets to be within your set rates, we have that for you.

• Here, the grommets are manufactured to offer a perfect seal right around lights in vehicles or signal lights as well

• If you want small rubber grommets from us, you will get that as well without spending a hefty deal on that as well

We know that people are spending a great deal of money on the square rubber grommet . So, they are not just going to invest in any of the grommet manufacturing company they will ever come across. Well, they do not have to when they have us for a change.

We are here working with industries of multiple sizes, bigger or smaller. So, we want our long rubber grommets to be easily available for all the people out there, in the market. In case, you are looking for the best grommets, we have that covered for you. On the other hand, you can give us a call for the thick rubber grommets as well, and we will never let you down.

We carefully listen to your requirements and design each mold to match your exact product, process, and quality needs.

We are committed to quality and use cutting-edge technology and rigorous quality checks to deliver accurate, precise, and dependable molds every time.

We design and manufacture high-precision tools, ensuring consistent part quality with reliable performance.

Our pricing is transparent and competitive, giving you high-quality custom rubber silicone molds without unnecessary cost or compromise.

industrial rubber grommets are widely used to protect and organize wires, cables, and other materials that pass through metal or plastic surface openings. With different applications come different requirements, including temperature resistance, chemical resistance, and durability. Choosing the right material for your industrial silicone grommets is essential to ensure they perform well in their intended environment.

Temperature resistance is important when choosing the material for your grommets. Different materials have different temperature limits, and selecting a material that cannot withstand your application's operating temperature can lead to the grommet's premature failure. For example, silicone grommets can withstand temperatures ranging from -50°C to 200°C, while EPDM industrial grommets can handle temperatures between -40°C to 125°C.

Chemical Resistance

If your application requires our grommets from Custom Rubber Silicone Molds to be exposed to chemicals or solvents, choosing a material that can withstand these substances is essential. Different materials have different chemical resistance properties, so it is important to consult with our rubber grommet supplier to select the right material for your specific application.

Durability

The durability of our rubber is crucial to ensure that they can withstand the wear and tear of daily use. Some materials, such as natural rubber, are more susceptible to degradation over time. Other materials, such as silicone rubber, have excellent durability and can withstand repeated compression and tension without losing shape or properties.

In The End

Choosing the right material for your rubber grommets seal is critical to ensure they perform well in their intended environment. By considering the application, temperature resistance, chemical resistance, durability, and cost, you can select the right material for your specific needs.