Low MOQ

Non Sticky

Total Design Support

Lab Tested Food Safe

Aerospace rubber mold parts come in forms of seals and gaskets, vibration dampers and insulation components

Manufacturers obtain high dimensional accuracy and consistency using high-level molding techniques

Silicone is among the most desirable materials in the electronics industry since it can withstand high temperatures

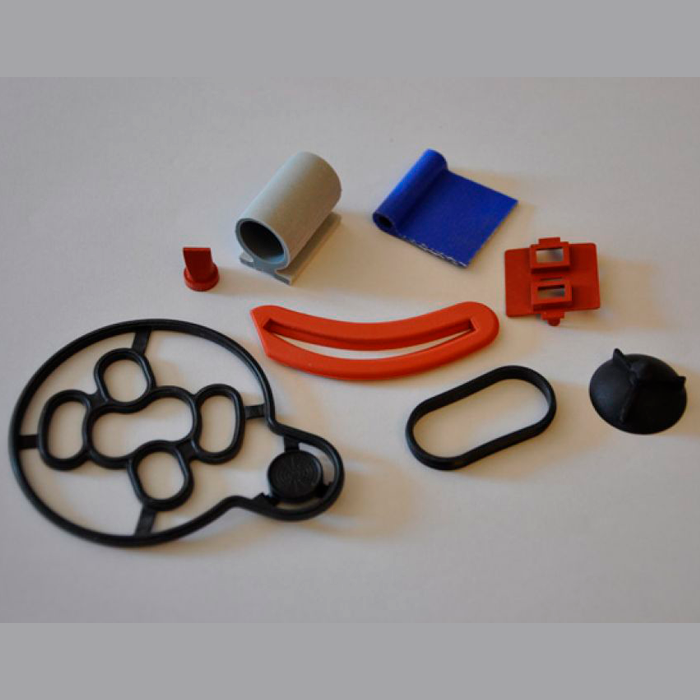

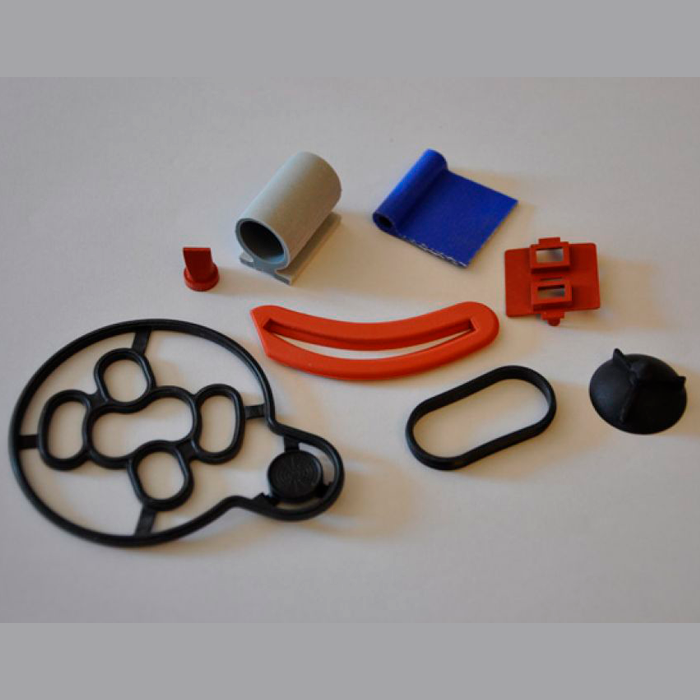

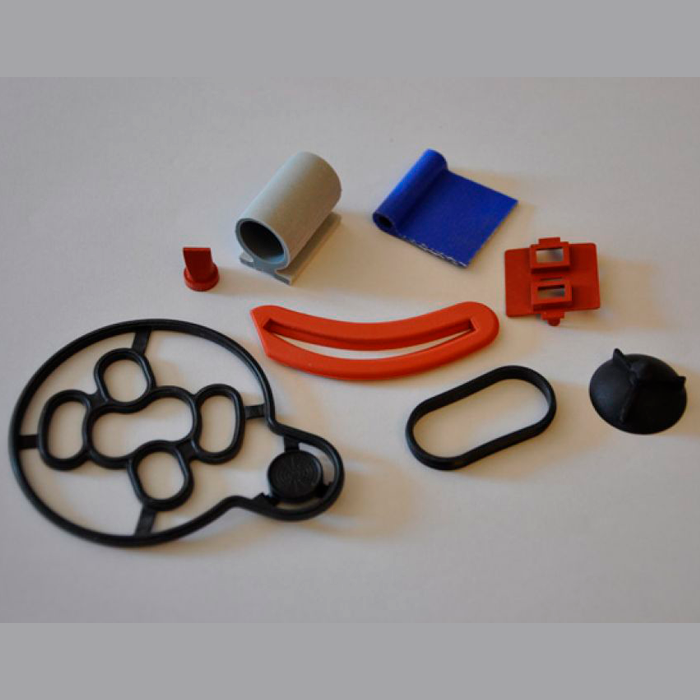

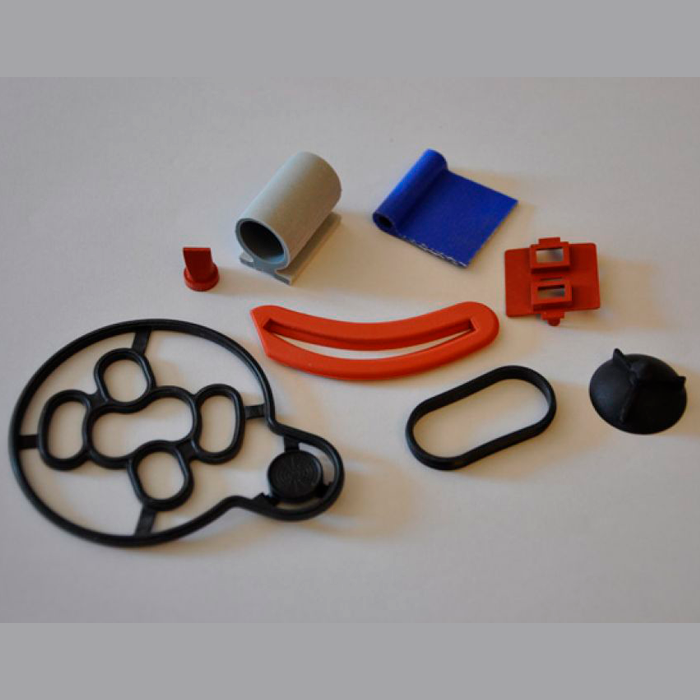

The advantages of silicone in the consumer goods sector include the flexibility, ability to withstand wear and tear, non-toxicity

So, the next time you are looking for u channel rubber extrusion , we request you to come and join us for the right items, hard to get from anywhere else. We can prove to be your experienced staff with enough knowledge about the industries that are using such channels and serve them right.

It is always important for you to check out the options, which are placed under c channel rubber extrusions before you make way for the right option. Some of the basic options over here are oval shaped, circular or square shaped U channels. There are so many other shapes available too for you to try. We are always there to help you make the right choice.

This is not the first time when you are eyeing for the extruded rubber u channel . You have been looking for these items for quite a long time but never got the opportunity to come across the best teams to help you with the best ones. When you have us by you side, there is no need to look for other names in this regard. We have been using the best materials for manufacturing these items, so that the products are able to last for a longer span of time. Once you have us by your side to help, there is no need to research any further.

We have been into this field of manufacturing extruded channel for the longest period of time. Our years of experience gave us the opportunity to know what our clients want and offer the same to them. So, we are able to help you in big ways possible and in this regard.

We carefully listen to your requirements and design each mold to match your exact product, process, and quality needs.

We are committed to quality and use cutting-edge technology and rigorous quality checks to deliver accurate, precise, and dependable molds every time.

We design and manufacture high-precision tools, ensuring consistent part quality with reliable performance.

Our pricing is transparent and competitive, giving you high-quality custom rubber silicone molds without unnecessary cost or compromise.

While looking for extruded rubber manufacturers , there is no shortage of businesses that are willing to act as your guides. There is a current need for rubber, for example. EPDM is often used as an alternative material for extrusion, but you need verify its quality to be safe. They invite you to consult with us about epdm extrusion if you're interested in learning more about this topic so you can make an informed decision.

The industries that use epdm extrusion profiles will evolve through time.

All settings are available

Different set of suppliers

They're hoping to become your go-to extruders so that you always get your extrusion products on time and at your specified address.

One of the crucial accents utilised in the auto industry and other sectors where glass products are constantly in use is rubber beading. Typically, the rubber beading is a strip of rubber that is placed along the rims of glasses to give them support so they can endure jerks and shocks. They are secured to the windows of several types of vehicles.

In residential settings, they are also employed as door and window sealants. Rubber beading completes any window trim perfectly. These beadings can be found on Custom rubber silicone molds in a variety of hues to complement the room's decor. The purpose of the rubber beading manufacturer is to take on the form of the spectacles. They are powerful but flexible.

Rubber beadings are made using a variety of rubbers. These are some examples of these rubber varieties.

Many Rubber Beading Types

The application determines the kind of rubber beading that should be utilised. There are primarily two types of rubber beadings offered by suppliers and makers of beads.

Type Rubber Beading: This is available in strips, and rubber-specific adhesive needs to be applied separately.

Foam Rubber Beading: This has a backing with an adhesive strip.

Rubber Beadings: Applications

Rubber beadings are used in a variety of industrial settings.