Low MOQ

Non Sticky

Total Design Support

Lab Tested Food Safe

Electronics silicone mold components play a very crucial role in creating the devices that require accuracy, insulation and long durability. Silicone is among the most desirable materials in the electronics industry since it can withstand high temperatures, it does not get wet and it offers great electrical insulation. They are used to shield delicate circuits, connectors, microchips, LEDs, and sensor enclosures against environmental stress. As smart devices become increasingly sophisticated, silicone molding makes every component properly fitting, consistent in its performance and stringent in its tolerance limits. Silicone components are used in consumer electronics, industrial machinery, medical devices, and IoT systems to ensure the stability and safety of the product.

Molding process can be used to achieve high complexity, strong sealing capability and superior durability. Also, the elasticity of silicone is used to absorb shock and vibration and protect sensitive electronic components in use. Electronics silicone mold parts are used to provide functionality and longevity to key pads and switches, cable seals and protective boots. With the ever-decreasing size of the electronics and their growing capabilities, the high-grade silicon components are still very essential in product designing reliably and efficiently.

Call Us At

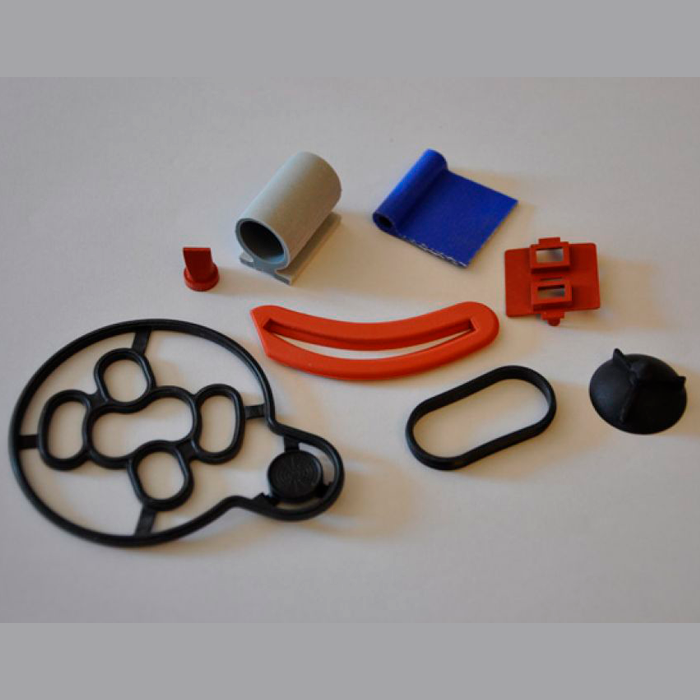

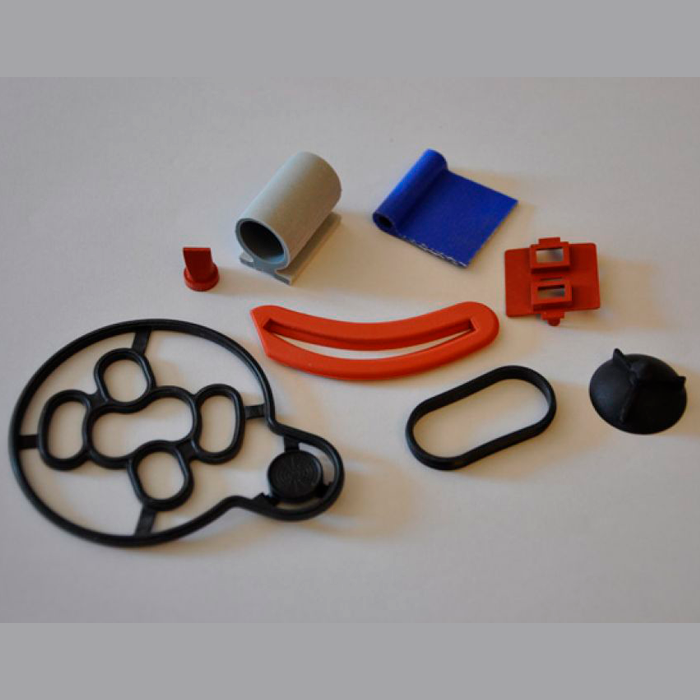

Rubber molds for electronic devices are crucial in production of durable, accurate, and well secured parts. These molds are employed to manufacture components which protect sensitive electronics against moisture, dust, impact and temperature changes. Detailed geometries needed in small electronic housings, keypad covers, vibration dampers, cable sleeves, gaskets and wearable-tech parts can be made using rubber molding.

Rubber has an outstanding elasticity that guarantees a safe fit and a high duration of services in portable devices, industrial control panel, domestic items, and high-tech equipment. Manufacturers prefer using rubber molds as they retain their dimensional quality, and enable high volume manufacturing without failure. Silicone, EPDM, neoprene, and NBR have characteristics of resistance to chemicals, heat or outdoor conditions. This makes the molded components stand steady even in the event that electronics are placed under strenuous situations. As equipment keeps being developed to be compact, lightweight and rugged, rubber molds are at the heart of the development of reliable sealing, flexible protection, and high-quality durability of the components used in all the modern electronic applications.

Custom molded silicone parts electronics offer ultra-specialized products to fulfill the design and manufacturing specifications of sophisticated devices. Silicone has excellent heat resistance, insulation property as well as flexibility, which makes it suitable in components that are required to be used under adverse conditions. Custom molding enables the manufacturer to develop parts to precisely fit the required specifications be it connectors, protective sleeves, keypads, enclosures, sensors and LED assemblies. These components guarantee the best sealing, stop penetration of moisture, vibration, and shielding of circuits against dust and contaminants. As the smart electronics, wearable technology, and IoT devices rapidly grow, custom silicone parts improve the performance and the life of the product. Silicone manufacturers have the option of various silicone grades depending on the hardness, texture and environmental resistance.

Consistency and durability are guaranteed in the mass production through precision molding process. Miniaturized electronics require custom silicone components in which space, tolerance and reliability are critical. Custom molded silicone parts are used to facilitate innovation in consumer, industrial, medical and communication technologies by providing unparalleled flexibility and toughness.

Precision rubber molding electronics industry facilitates the production of accurate, dependable, and protective components that are needed by modern products. It is done by high-technology molding methods injection, compression and transfer molding to make components incredibly detailed and dimensionally stable. Rubber parts that are molded with precision play an important role in sensor housings, keypad elements, O-rings, vibration isolators, cable seals and micro-component gaskets. The electronics sector requires materials that are resistant to heat, electromagnetic radiation, mechanical force and environmental factors; rubber compounds such as silicone, EPDM, nitrile, and fluorocarbon will provide superior performance in these respects.

Precision molding guarantees tight tolerances, repeatability and long-term reliability which are essential in consumer electronics as well as industrial electronics. These shaped components can be useful in ensuring effective functionality by avoiding the entry of contaminants, absorbing impact, and holding fragile components. The demand of perfectly engineered components made out of rubber rises as electronics are shrinking and becoming more sophisticated. Accurate rubber molding also makes the devices functional, durable and safe, which is favored to contribute to the further development of the global electronics production.

Custom rubber silicone molds play a vital role in delivering high precision, durable and correctly sized components in all industries. When you choose us for your custom mold needs, you are choosing a trustworthy partner committed to precision and quality.

Electronic enclosure silicone gaskets are created in order to offer superior sealing, insulation and environmental protection to delicate electronic systems. The natural ability of silicone to withstand high temperatures, UV radiation, chemicals and moisture is also a property that makes it a good choice in enclosures in industrial automation, in outdoor electronics, consumer devices, telecom equipment and medical instruments. Such gaskets allow neither water, dust nor contaminants to get into the enclosure and maintain the internal circuitry intact and working.

Silicone gaskets are also very resistant to compression sets and therefore they can be used to remain sealing intact even after several years of pressure and heat exposure. Being flexible, they are appropriate with complicated shapes and bespoke enclosures. Silicone gaskets are used to prevent vibration, reduce noise, and enhance the stability of the devices, besides protection. With electronic devices being put into harsher or rougher settings, such as the outdoors, reliable gaskets on enclosures are more necessary than ever before. Electronic enclosure silicone gaskets offer robustness and dependability over an extended period of electronic functionality whether it is junction boxes, control panels, battery cases, or sensor modules