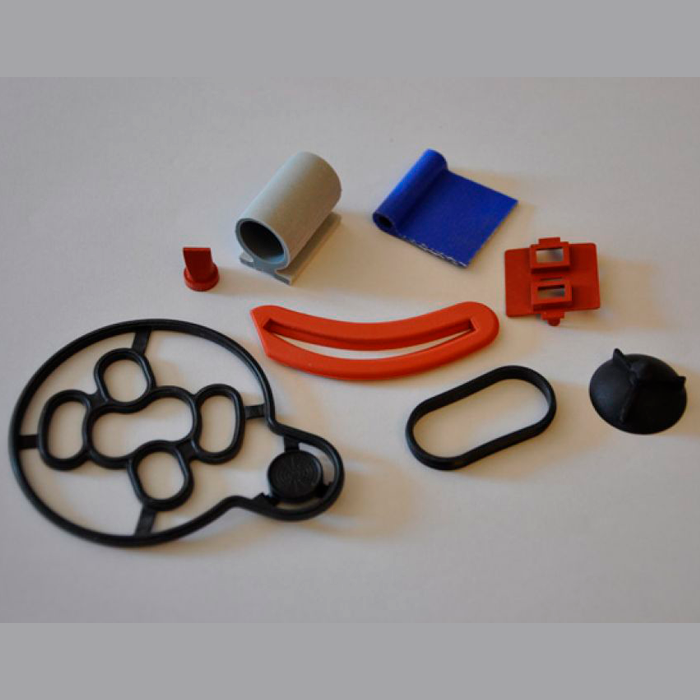

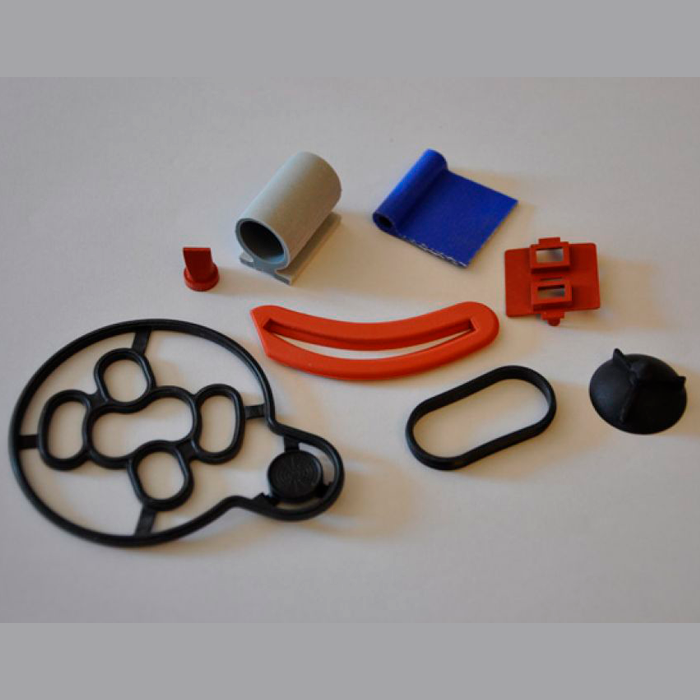

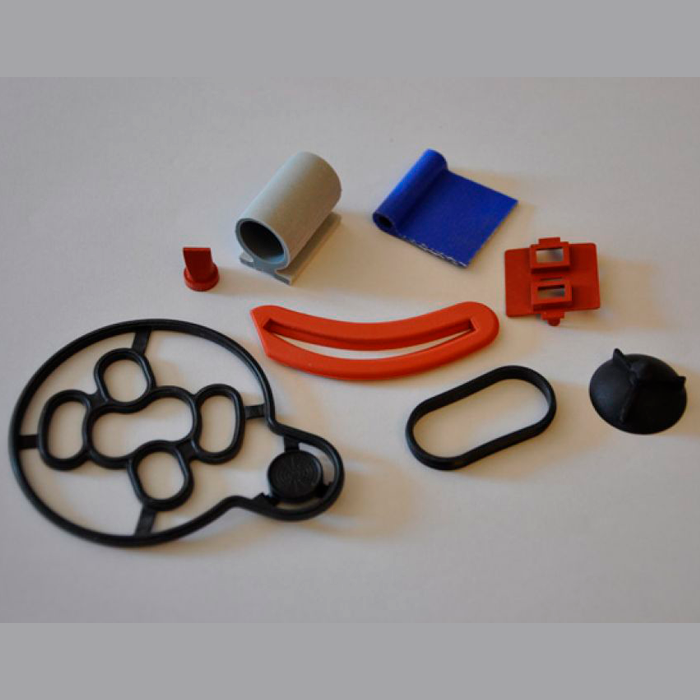

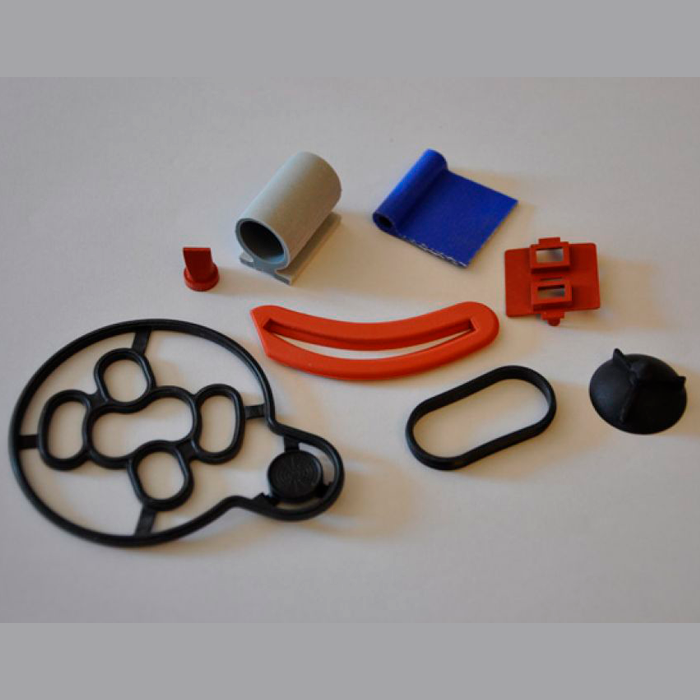

Aerospace rubber mold parts come in forms of seals and gaskets, vibration dampers and insulation components

Manufacturers obtain high dimensional accuracy and consistency using high-level molding techniques

Silicone is among the most desirable materials in the electronics industry since it can withstand high temperatures

The advantages of silicone in the consumer goods sector include the flexibility, ability to withstand wear and tear, non-toxicity

Push on edge trim rubber seals are a type of sealing material that can be easily installed without the need for adhesives or tools. They are designed to fit over the edge of a surface, providing a secure and tight seal against moisture, dust, and other environmental elements.

Push-on edge trim rubber seals are made of a flexible rubber material that can easily conform to the shape of the surface it is applied to, providing a reliable and long-lasting seal. They are available in a variety of sizes and shapes, making it easy to find the right fit for any application. Additionally, push-on edge trim rubber seals are resistant to temperature changes, making them suitable for use in a wide range of environments by Custom Rubber Silicone Molds.

The edge trim rubber helps in finishing and protecting the metal edges that stay exposed. U can choose from black or custom-colored trims and textured finishes. The rubber edge trim seal we manufacture are of the highest quality and provide strong grip with the interior tongues. You can buy materials for edge trim from us in build or get finished products to suit your requirements. The edge trim seals are common in machine guard, car doors, surfaces of metal sheets and other kitchen equipment.

The edge trim seal we offer to customers depends on the requirements of the clients. For instance, some customers may require the trim seals to resist to fluids, such as machine oil and water. Apart from this resistance against weather, ozone, and sunlight may also be necessary.

Custom Rubber edge trim is a type of rubber seal that is designed to provide a secure and tight seal between two surfaces. It is commonly used in automotive, marine, and construction applications to protect against dust, moisture, and other environmental elements. The trim is made of a flexible rubber material that can easily conform to the shape of the surfaces it is applied to, providing a long-lasting seal.

Our rubber edge trim is available in a variety of shapes and sizes, allowing for a custom fit to meet specific application requirements. It is also resistant to harsh weather conditions, making it suitable for use in outdoor environments. Additionally, rubber edge trim can absorb vibrations and reduce noise, making it an ideal choice for sealing doors, windows, and other moving parts.

Features of Our Silicone Edge Trim

Silicone edge trim is a type of sealing material that is known for its durability and resistance to high temperatures and harsh weather conditions. It is made of a flexible silicone material that can easily conform to the shape of the surfaces it is applied to, providing a secure and tight seal. Silicone edge trim is also resistant to UV radiation and ozone, making it suitable for outdoor use. It can absorb vibrations and reduce noise, making it ideal for use in sealing doors, windows, and other moving parts. Additionally, silicone edge trim is available in a variety of sizes and colors, allowing for a custom fit and aesthetic appeal.

We carefully listen to your requirements and design each mold to match your exact product, process, and quality needs.

We are committed to quality and use cutting-edge technology and rigorous quality checks to deliver accurate, precise, and dependable molds every time.

We design and manufacture high-precision tools, ensuring consistent part quality with reliable performance.

Our pricing is transparent and competitive, giving you high-quality custom rubber silicone molds without unnecessary cost or compromise.

We are a customer-driven company and our products demonstrate our principles and ethics. Our ability to develop solutions and services irrespective of the situation makes us one of the leading providers rubber edge seal trim at competitive rates. The custom sealing solutions we create remain undeterred amidst the challenges and the advanced manufacturing techniques turn our dream into reality.

Rubber corner trim: Sealing solutions

The rubber corner trim is made from sponge or solid rubber and other quality materials. Our products have high percentage of elongation and meet the requirements of the clients suitably.

Rubber edge trim seal: Made to order

The rubber products define our leadership qualities and we use all-purpose materials to withstand harsh weather conditions. To meet your requirements, order our rubber trims today.

U channel rubber edge trim is a type of rubber seal that is shaped like a "U" and designed to provide a secure and tight seal between two surfaces. It is commonly used in automotive, marine, and construction applications to protect against dust, moisture, and other environmental elements. The U shape design of the rubber edge trim allows for easy installation by simply pressing it onto the edge of the surface, providing a long-lasting and reliable seal.

Custom Rubber Silicone Molds rubber material is flexible and can easily conform to the shape of the surfaces, providing a custom fit to meet specific application requirements. U channel rubber edge trim is available in a variety of sizes and thicknesses, making it suitable for use in a wide range of applications. Additionally, it is resistant to harsh weather conditions, making it suitable for use in outdoor environments. It can also absorb vibrations and reduce noise, making it an ideal choice for sealing doors, windows, and other moving parts.

U channel edge trim is a versatile and durable rubber seal that provides a secure and tight seal between two surfaces. The U-shaped design of the trim allows for easy installation by simply pressing it onto the edge of the surface. The rubber material is flexible and can easily conform to the shape of the surfaces, providing a custom fit to meet specific application requirements.

Our U channel edge trim is available in a variety of sizes and thicknesses, making it suitable for use in a wide range of applications. It is also resistant to harsh weather conditions and can absorb vibrations and reduce noise, making it an ideal choice for sealing doors, windows, and other moving parts. Additionally, it is lightweight and easy to install, making it a popular choice for both professional and DIY applications.

Rubber linings are a protective layer made of rubber material that is applied to the interior surfaces of various equipment and machinery. The primary purpose of rubber lining is to protect the underlying surfaces from corrosion, abrasion, and other forms of damage. Rubber linings are commonly used in industrial applications, such as in tanks, pipelines, and chutes, where the equipment is exposed to harsh chemicals, abrasive materials, or extreme temperatures.

Our rubber linings are also used in the mining industry, where they are applied to the interior surfaces of crushers, screens, and other equipment to protect against wear and tear caused by abrasive materials. In the food and beverage industry, rubber linings are used to line tanks and containers to prevent contamination and provide a clean surface for food processing.

Rubber linings are available in a variety of thicknesses and materials to suit different application requirements. They are flexible and can be easily molded to fit the shape of the equipment, providing a custom fit and long-lasting protection. Overall, rubber linings are an essential component in ensuring the longevity and efficient operation of industrial equipment and machinery.

Rubber lining companies like us specialize in providing rubber lining solutions to various industries, including mining, chemical, and food and beverage. Our company offer a range of services, including the design, installation, repair, and maintenance of rubber linings for equipment and machinery. Our high-quality rubber materials are resistant to abrasion, chemicals, and extreme temperatures to ensure the longevity and efficiency of the equipment.

Custom Rubber Silicone Molds employ experienced technicians and engineers who have the expertise to provide custom solutions to meet the specific needs and requirements of their clients. Overall, rubber lining companies play a crucial role in protecting and prolonging the life of industrial equipment and machinery.

We are the leading rubber corner manufacturers that specialize in designing and producing rubber corner products used for protection and safety purposes in various industries. We create rubber corner guards, bumpers, and protectors for use in warehouses, loading docks, parking garages, and other industrial and commercial settings. We use high-quality rubber materials to create durable and long-lasting products that can withstand impacts and protect against damage.

We also offer custom design and manufacturing services to meet the specific needs of their clients. Rubber corner manufacturers play a critical role in providing reliable and effective safety solutions to protect people and property in a variety of environments.