Custom Extruded

Seals & Gaskets

Precision Profiles

Durable Materials

Chemical Resistance

Custom Shape & Size

- Home

- Custom Extruded Seals And Gaskets

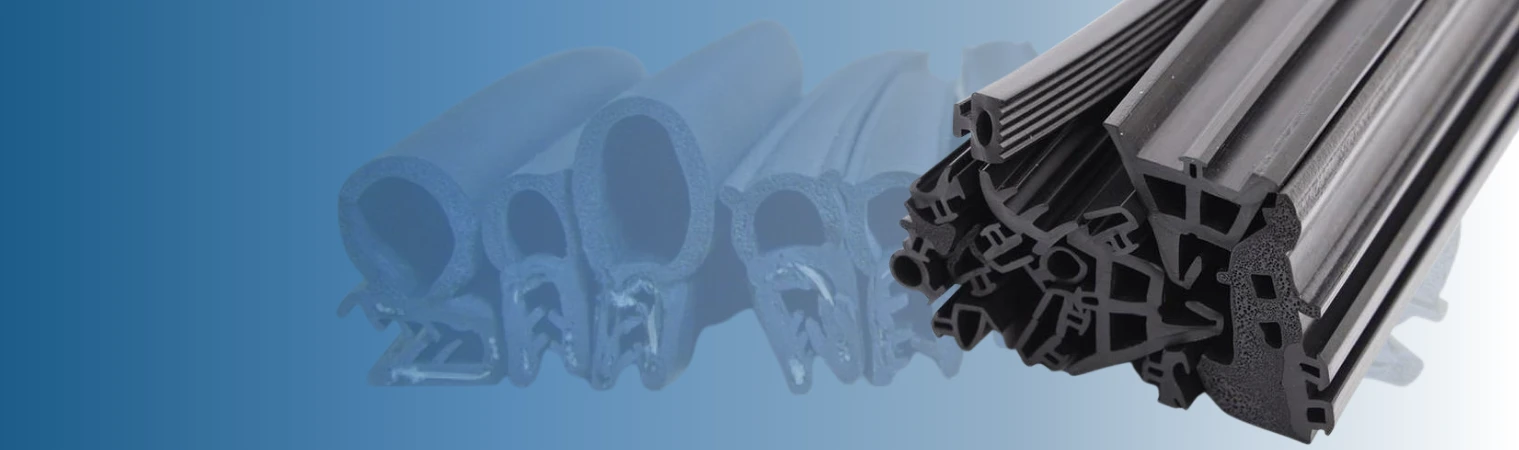

Dependable and Custom Extruded Seals and Gaskets

Seals and gaskets made through extrusion play a critical role in ensuring the safety, efficiency, and durability of numerous products across many industries. These important components can be found in everything from automotive and aerospace to construction, medical devices, and electronics equipment. They contribute significantly to the smooth and effective operation of machinery and systems.

We specialize in making custom extruded rubber gaskets, precisely engineered to match specific sizes and performance requirements. This approach guarantees they fit perfectly, provide top-notch sealing, and can stand up to tough conditions like heat, pressure, chemicals, and temperatures.

The manufacturing of extruded seals and gaskets is done through advanced techniques. It involves forcing rubber compounds through precise dies to create continuous lengths of shape. These lengths can then be cut, joined, or spliced to create the exact shapes needed. By choosing quality extruded rubber products, businesses can extend the life of their equipment, cut down on maintenance expenses, and boost their overall performance. At Seal and Gaskets, we provide small quantities for testing or large quantities of extruded seals and gaskets for reliable, long-lasting performance, even in the most demanding conditions.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Custom Extruded Seals and Gaskets In Industry

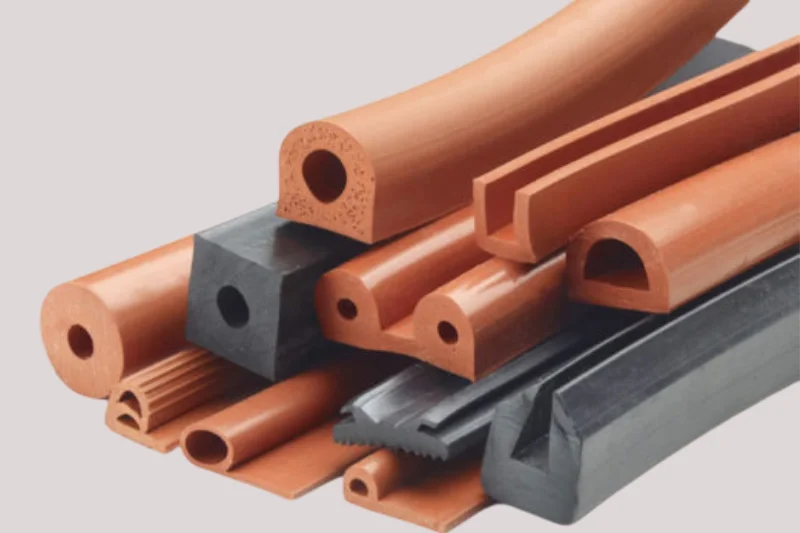

Our Products

Extruded Seals and Gaskets Manufacturing Process

Extruded seals and gaskets manufacturing requires a thoughtful combination of precise design and cutting-edge materials.

- Material Selection: Choosing the right rubber compound that can withstand specific conditions and provide temperature, chemical, or weather resistance.

- Extrusion Process: A process where rubber is pushed through a shaped opening to create long pieces like D-seals, P-seals, U-channels, or unique shapes.

- Curing & Vulcanization: The heat treatment process is used to make rubber profiles tougher and durable.

- Cutting & Splicing: The profiles are cut to specific sizes and then joined together, either by splicing or bonding, to create extruded gaskets as needed.

- Quality Testing: We test the rubber parts to confirm they meet the required standards for dimensions, hardness, and durability before delivery.

Trusted Custom Extruded Seals and Gaskets Companies

As one of the leading custom extruded seals and gaskets companies, we are dedicated to giving you the best sealing solutions, tailored to your industry's needs. Our high-quality seals are built to last and work perfectly, even in tough environments with extreme temperatures, pressure, and chemicals. With a deep understanding of materials like silicone, EPDM, neoprene, and Viton, we make products that match exact specifications.

When you choose to work with us, you can be confident in getting reliable seals, minimizing equipment interruptions and meeting all the necessary industry regulations. Choosing us as your expert extrusion partner means you'll get access to innovative design ideas, prototype development, and efficient manufacturing all resulting in improved sealing performance.

Countries

Industries Served

Projects

Clients

Why Choose Custom Extruded Rubber Gaskets & Seals?

When you compare them to standard ones, custom extruded rubber gaskets and seals clearly offer a better, long-term value for your investment.

- Perfect Fit: We design our rubber products to meet your exact size and specification requirements.

- Material Flexibility: We provide a range of options such as EPDM, silicone, nitrile, neoprene, and Viton to suit your requirements.

- Enhanced Performance: Our rubber products are made to last, resisting damage from tough environments including extreme temperatures, oils, chemicals, and UV rays.

- Versatility: They're also incredibly versatile, providing excellent seals against air, water, gases, and various liquids.

Importance of Custom Seals and Gaskets

Custom seals and gaskets help equipment last longer, work better, and perform more precisely. We provide custom sealing solutions for diverse industrial and mechanical applications.

- Custom seals and gaskets prevent leaks, ensuring reliable system performance in demanding industrial and commercial applications.

- They extend equipment lifespan by minimizing wear, abrasion, and environmental damage.

- These extruded seals and gaskets improve efficiency by reducing fluid, gas, and energy loss across different systems.

- The proper materials provide resistance against chemicals, temperature changes, and harsh environmental conditions.

- They ensure an accurate fit for complex equipment, reducing downtime and costly maintenance requirements.

- Custom solutions improve safety by preventing contamination, hazardous leaks, and system failures in critical industries.

How to Choose the Right Manufacturer?

When choosing a custom extruded seals and gaskets manufacturer, keep these points in mind:

- Industry Experience: Choose a manufacturer that has a solid track record with seals and gaskets, especially within your specific industry.

- Material Knowledge: They must have the material understanding to suggest the best elastomer for handling specific temperatures, pressures, and chemical conditions.

- Certifications and Standards: They should have the right certifications, such as ISO or FDA, or meet other industry standards, to ensure a quality product.

- Support and Service: A trustworthy partner should provide design help, prototyping services, and quick after-sales support.

Choosing the right sealing solution is crucial for top performance and dependability. At Seals and Gaskets, we specialize in crafting custom molded seals and gaskets designed to meet even the toughest sealing demands. Need durable seals and gaskets, or a dependable partner for custom-made molded components? Call us today to talk about what you need. Our team is here to help! We provide expert advice and deliver custom solutions to the specific needs of your business.

Ready to See your Idea For Seal & Gasket

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.