Materials Used

Leak Prevention

Durable & Flexible

Customizable Design

Temperature Tolerance

Corrosion Protection

- Home

- Materials

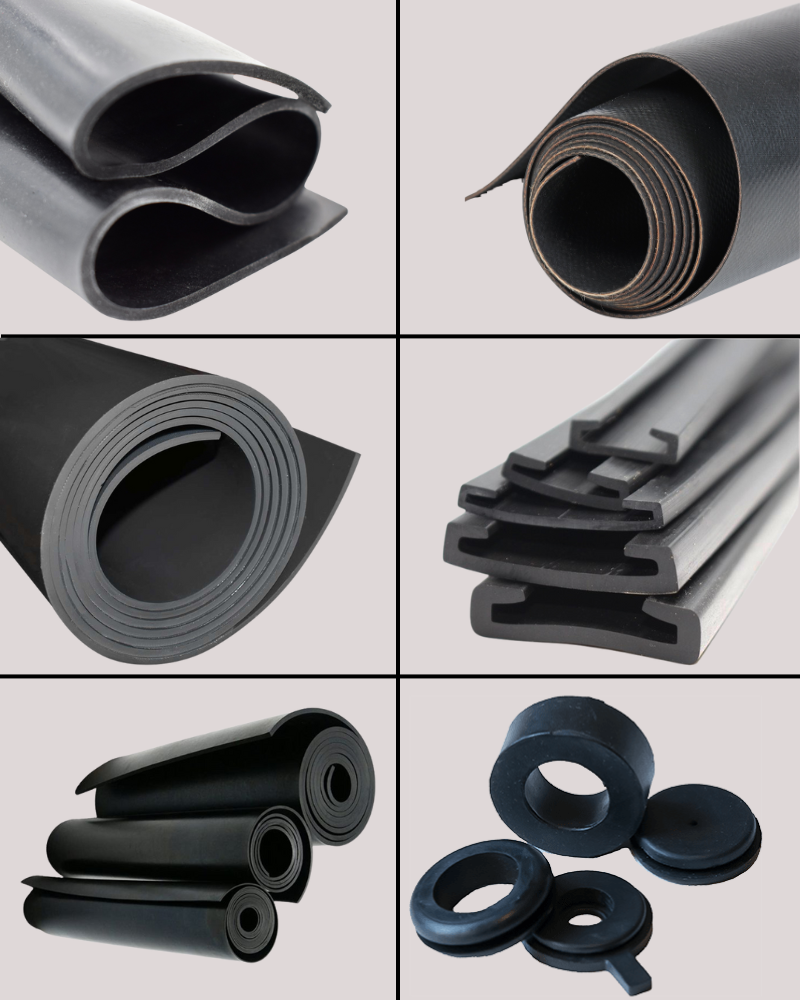

Material We Use for Making Custom Rubber Bellows

We're experts at manufacturing custom rubber bellows as per your specific needs. We use a range of durable yet versatile materials, including EPDM, silicone, Hypalon, Neoprene, Butyl, Nitrile, natural rubber, polyurethane, and PVC to manufacture a variety of rubber bellows. Rubber bellows are vital in many industries, from automotive to manufacturing, because they protect sensitive components from dust, dirt, and moisture while letting them move and expand smoothly.

We choose each material because of its unique qualities, ensuring they meet the specific demands of your application. At Custom Rubber Bellows, we carefully select materials to guarantee outstanding resistance to heat, chemicals, oils, and rough environmental conditions, all while maintaining the necessary flexibility and durability. By blending precise manufacturing with top-quality rubber compounds, we make sure our bellows provide reliable and long-lasting performance. This helps minimize the need for maintenance and boosts the efficiency and safety of your machinery or equipment.

Variety of Material Choices

EPDM Bellows

EPDM bellows, crafted from a type of synthetic rubber, are known for their exceptional ability to withstand high temperatures, ozone exposure, sunlight, and general environmental wear and tear. This durability makes them a great choice for u automotive and outdoor applications. They also stand up well to acids, alkalis, and steam, making these bellows perfect for things like HVAC systems, water pumps, and equipment that handles chemicals. Plus, their flexibility lets them move and expand smoothly, providing dependable protection in systems that are always changing.

Silicone Bellows

Silicone rubber bellows are built to handle extreme temperatures, both super low and super high, which makes them perfect for use in industries like aerospace, food processing, and medical devices. Not only is silicone really resistant to chemicals and doesn't react with other substances, but it also ensures safety in sensitive settings. Over time, it stays flexible and keeps its shape uniform even after repeated bending and movement.

Hypalon Rubber Bellows

Hypalon rubber bellows are valued for their excellent resistance to chemicals and solvents. They hold up well in harsh conditions where they might be exposed to oils, fuels, and strong chemicals, which makes them a good choice for use in industrial and marine settings. Hypalon stays flexible across a wide temperature range and is durable against damage from ozone and UV light.

Neoprene Rubber Bellows

Neoprene rubber bellows are super popular in industrial and mechanical settings because of their impressive ability to withstand oils, chemicals, and the elements. Plus, they're flame-resistant, which makes them perfect for situations where safety is a top priority. These bellows are known for being flexible and tough, ensuring dependable sealing whether they're used in constantly moving parts or static applications.

Butyl Rubber Bellows

Bellows made from butyl rubber are a great choice for preventing air and gas from leaking. They hold up well against chemicals, outdoor conditions, and sunlight. This type of rubber is also flexible, so it can maintain a good seal even in tough environments. That makes butyl rubber bellows well-suited for protecting sensitive components in automotive, aerospace, and industrial systems.

Nitrile Rubber Bellows

Nitrile rubber, commonly known as Buna-N, is an excellent choice for bellows because it stands up well against oils, fuels, and fluids derived from petroleum. This makes it ideal for use in automotive, hydraulic systems, and pneumatic equipment. Beyond its chemical resistance, nitrile also withstands wear and tear, is mechanically strong, and retains its flexibility. This ensures the bellows will continue to function properly, even in constant movement and harsh environments.

Natural Rubber Bellows

Natural rubber bellows are a popular choice for their exceptional elasticity, durability, and resilience. They provide a great defense every day use while still being flexible in situations where movement is constant. While they don't hold up as well against chemicals and high temperatures as synthetic rubbers, natural rubber bellows are a great choice for everyday industrial uses, where resisting wear and tear and maintaining elasticity are the most important.

Polyurethane Bellows

Polyurethane bellows combine the strength of plastics with the flexibility of rubber. They are highly wear-resistant, abrasion-resistant, and chemical-resistant, which makes them suitable for heavy-duty industrial applications. Polyurethane bellows provide long service life in demanding mechanical environments and maintain flexibility even under repeated stress.

PVC Rubber Bellows

PVC rubber bellows are cost-effective solutions for moderate-duty applications. They are resistant to corrosion, water, and many chemicals, making them ideal for protective bellows in machinery and piping systems. PVC bellows provide good flexibility and ease of installation while providing reliable protection against dust and debris.

Why Choose Our Custom Rubber Bellows?

At Custom Rubber Bellows, we carefully select the best materials to make our bellows. Our rubber bellows are perfectly designed to fit the specific requirements of automotive, aerospace, medical, and various other industrial applications. The key reasons to choose our customised rubber bellows are:

- Durable Quality: Durable Quality: Our rubber bellows are manufactured using top-quality materials, ensuring that they'll keep performing well over time. They're durable enough to handle wear, tear, and tough conditions with ease.

- Flexible Design :We make highly flexible bellows, designed to fit a wide range of industrial applications. This flexibility helps them smoothly absorb movements, vibrations, and any slight misalignments.

- Perfect Fit :Every bellow is specifically designed to fit the precise size and needs of your equipment. This ensures an effective sealing and works seamlessly with your equipment.

- Shock Protection : Our custom bellows also help protect your machinery by reducing vibrations and effectively absorbing shocks. This leads to a longer lifespan for your equipment and less unexpected maintenance.

- Chemical Resistance : We use materials that withstand oils, fuels, and various chemicals. This makes our bellows a great fit for demanding industries like chemical processing, oil and gas, and water treatment plants.

Custom Solutions for Every Industry

We manufacture custom rubber bellows to meet the distinct requirements of various industries. We provide a choice of materials such as EPDM, silicone, nitrile, and polyurethane that guarantee the best performance and protection for your machinery or equipment. Our bellows provide dependable sealing, effective vibration absorption, and strong resistance to heat, chemicals, and harsh environmental conditions, making them suitable for a wide range of applications.

Ready to See your Idea For Custom Rubber Below

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.